Other Parts Discussed in Thread: ADS122C04,

Tool/software:

I have been using another chip and a separate temp sensor for a medical weighing application.

However, I wanted to try out ADS122C04, and I got the evaluation board.

I have it connected to my SOC (nrf9160DK) via I2C. I do not seem to be able to get any sensible data.

This is the terminal communication I do:

i2c scan I2C_3

0 1 2 3 4 5 6 7 8 9 a b c d e f

00: -- -- -- -- -- -- -- -- -- -- -- --

10: -- -- -- -- -- -- -- -- 18 -- -- -- -- -- -- --

20: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

30: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

40: 40 -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

50: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

60: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

70: -- -- -- -- -- -- -- --

2 devices found on I2C_3

-> The chip is found at 0x40 (the device at 0x18 is separate temp sensor for comparison)

i2c write I2C_3 0x40 0x06 // reset chip

i2c write I2C_3 0x40 0x4C 0x10 // Setting TS bit to 1 (enable built-in temp sensor)

i2c write I2C_3 0x40 0x08 // Starting conversions

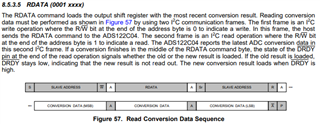

i2c write I2C_3 0x40 0x10 // Sending RDATA command

i2c read I2C_3 0x40 3 // Read data

I get 00000000: 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 |........ ........|

So clearly I am doing something wrong, but what?

The other temp sensor connected on the same bus gives correct results...

These are my immediate goals:

1) Get the internal temp sensor working

- Do I need to set the jumpers to something special (other than default on the board)?

- Are my commands correct?

- What do I need to do

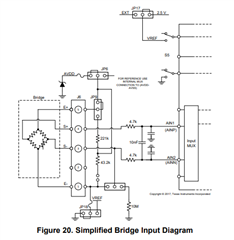

2) Connect my wheatstone bridge, set the gain to 128 and take a reading

- How/where do I connect my bridge to the evaluation kit (my bridge works on my HX711, but I not want to try this device)

- How do I correctly set the gain and set the other relevant parameters?

Sorry for the basic questions, but one has to start somewhere