I've post this writing in an old thread but think it is not coherent, so I'm posting it in a new thread.

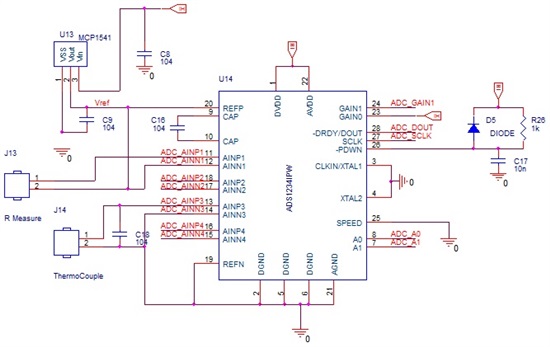

I'm using ads1234 and see its operation is weird. I did connect the part as follow: both XTAL1 and XTAL2 to 0V, SPEED to 0V,t PWDN to VDD via RC network (1kOhm and 10nF), all digital pins (SCLK, GAIN1, GAIN0, A1, A0) go to 0V.

As I see waveform on DRDY/DOUT pin on my ossiloscope, the pin pulse low to high to low every 11ms, pulse width is 4.2 us. I suspect this is 80 SPS mode but the hardware is in 10 SPS mode? The results retrived from adc is random and unstable. As I turn on and off the board, sometimes (about 10% of all cases), the pin pulse low to high to low every 100ms and the result is correct.

I don't know why the ic operation mode changes and the result is incorrect. Could you please help me on this issue? Thanks a lot.

Best regards,

T.anh