Other Parts Discussed in Thread: ADS1259, ADS125H01, ADS124S08

Tool/software:

In my project, I will develop a board: four channel datalogger for the strain, RTD sensors and also ratiometric measurement. Firstly I designed a board which I used two ADS1220 as an ADC.

0-5V measurement,

1-128 PGA gain,

120 ohm switch selected resistors for 4-20ma current measurement.

But I need help about the design.

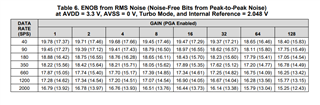

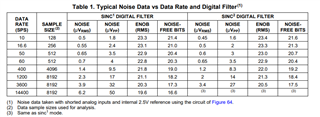

1) When I writing code for the design I confused about the resolution of the ADS1220 is sufficient or not. In the datasheet the noise free bit is 13.42 bits in Turbo Mode and 660SPS datarate. I used digital filter: mean filter 12 reading for each channel, total readings are 24 for each ADC. The required time is about 1 / ((660/2)/12)= 36ms. The time is sufficient for my design but the noise free bit not. I need 16 bits resolution at least for each channel. Can the mean filter or other improve noise free bits?

2) Also I need 0-10V analog input for the industrial level measurement. Should I use the voltage divider and unity gain opamp? Any other suggestion.

3) Also I confused about using two or more ADC (ADS1220) each channel or multiplexing ADS1259 and PGA280-281. Is this a good choice for the 4 channel design.

But In this solution I have some question:

- I need 1200SPS for scanning for channel and 18.4 noise free bits is enough for me but Do the gain and multiplexing stages affect this noise free bits. Also will I experience the crosstalk interference for channel to channel.

- In ratiometric measurement, I will switch the internal reference to the external reference. For example I connect loadcell to the channel_1, RTD to the channel_2, thermocouple to the channel_3, ... Can I change the reference ( 2.5V internal ref. to 5V external ref. and vice versa) when switching from channel to channel. Does the settling time affect the total time or SPS time?

- For the ratiometric measurement I will use %0.2 LDO regulator for the excitation voltage (For example 350ohm strain gauge) and external reference input but for the thermocouple I want to use 2.5V internal reference. Any other suggestion?

- Can I use ADS1259 internal reference to output from REFOUT pin as a sensor excitation with buffer and transistor like a linear regulator. Is this a good approach? If yes any suggestion about current limiting for the short circuit?