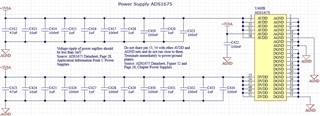

Other Parts Discussed in Thread: LP2992, TPS82130

Tool/software:

We use the ADS1675 in one of our products which is already in mass production. Normally it works fine. But roughly every 100th device we see a strange behavior.

We use the ADS1675 to convert an analog signal from a detector measuring an actuators position. At first the ADS1675 works fine, but then after about an hour, when the component is warmed up, the output signal seems to be superimposed by a kind of square wave signal.

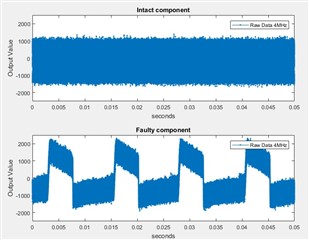

To illustrate this behavior, I recorded data with an intact component and a warmed up faulty component. Both components are measuring an actuator at standstill. So actually only the measurement noise would be recorded.

As you can see on the image below the intact component indeed shows only measurement noise. But the faulty component is superimposed by a kind of square wave signal with a frequency of approximately 80 Hz. When I spray cooling spray directly on the ADS1675 this behavior disappears, and I get normal measurement noise. But about 50 seconds later when the component has warmed up again, the strange behavior returns.

Is that a know issue of this component? Do you have any ideas where this behavior comes from?

We use the following configuration:

- High speed mode (4000 kSPS)

- Low latency filter with fast response

- LVDS interface