Tool/software:

Hey team,

I am a beginner in embedded systems, and I am currently working with STM32 chips to communicate with the ADS7054. However, there are some aspects of the ADS7054 chip that I don't fully understand. I have a few questions that I would like to ask:

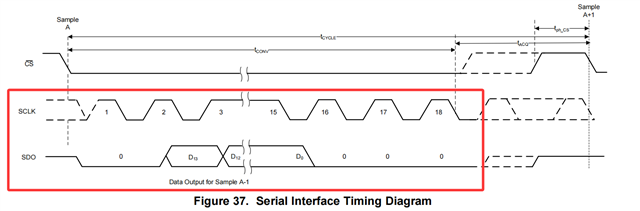

1.How should the phrase 'provide SCLKs in the serial transfer frame' mentioned in the datasheet be understood?Is it just a simple delay process?

My understanding is that the SPI communication of the STM32 chip sends some dummy data to the ADS7054 to provide the changes in high and low levels.

Taking the CNV State as an example:

void SendSCLK18Cycles(void)

{

uint8_t dummyData = 0x00;

for (int i = 0; i < 18; i++)

{

HAL_SPI_Transmit(&hspi1, &dummyData, 1, 100);

}

}

2.Will the SDO return a total of 18 bytes of data for the CNV State?

3.For the OFFCAL State, does it need to be calibrated before each data acquisition, or is it sufficient to calibrate only once when powered up?

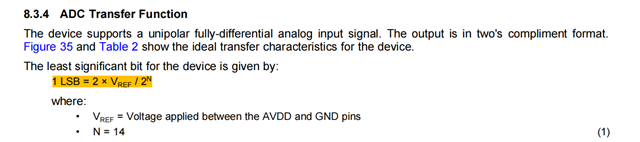

4.How should I process the data received via SPI? Should I directly use the formula mentioned in section 8.3.4 for the calculation?

I hope to receive an answer from the relevant person(s).

Thanks!

Zhixin Ni