Other Parts Discussed in Thread: ADS1115

Tool/software:

Hi

I am working on a project where I need to read the voltage of two sensors.

Sensor 1 is alphasense_pidx-a-004_datasheet_nov24_en_1.pdf

Sensor 2 is alphasense_isb_datasheet_en_1.pdf

The maximum voltage this sensor will output is 2.5V, but the region I will be measuring is most likely in the millivolt range, between 0.2V and 0.5V.

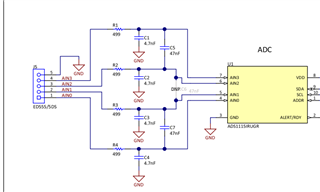

The ADC and the sensor will be placed on a daughter PCB, which will interface with I²C and 5V. If needed, I will also include a 3.3V LDO for I²C. The VCC, GND, and I²C signals will pass through a common-mode choke to minimize noise interference.

I would like to know if this device is suitable or if you would recommend a better alternative. The only requirement is that it must have an I²C interface and at least four channels. Sensor 1 provides a single signal, while Sensor 2 outputs two signals. If possible, I would like to connect the fourth channel to GND to calculate the offset—would this be recommended? Or should I follow the shorting suggestion in the datasheet?

I have a few questions:

- Should I use 5V as my reference? Am I correct in understanding that since the REF is differential, the top reference value will be 2.5?

- Should I include additional filtering, or would it be better to use the internal 2.048V reference? I do not expect my signal to exceed 2V.

- I plan to take readings multiple times per minute unless it is recommended to do so every few seconds and apply averaging. How do I determine the optimal data rate setting? Since the ADC is Delta-Sigma, I believe it performs oversampling and filters outliers—am I correct?

- Since the device has a gain setting, would it be advisable to initially take a sample at gain 1 and, if the voltage is below 0.5V, switch to gain 4 for better resolution? Is this a recommended practice, or should I keep the gain at 1 for my application?

I appreciate your guidance on these points.