Other Parts Discussed in Thread: AFE4300, DAC80516, DAC60516, DAC81416, DAC61416, PGA849, DAC61401, OPA455, OPA462, OPA596, OPA593, PGA281, PGA280, OPA2596

Tool/software:

Hi Team,

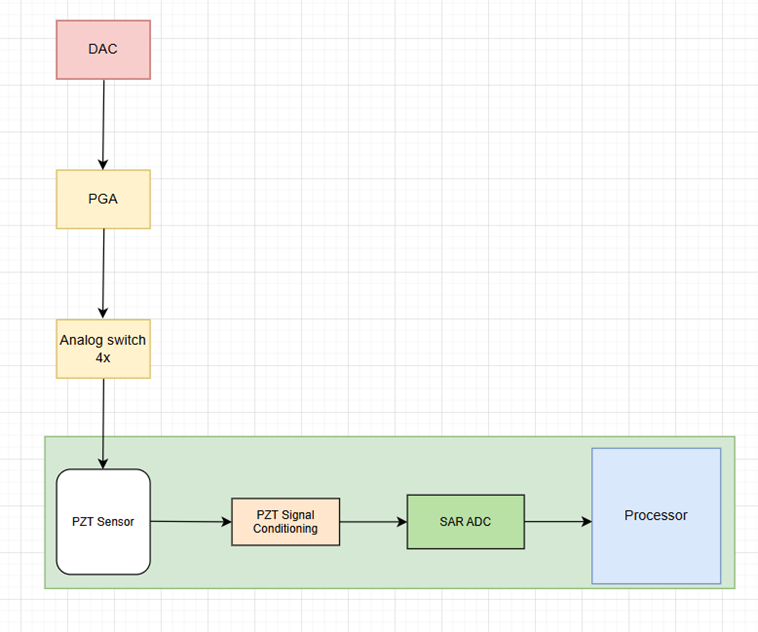

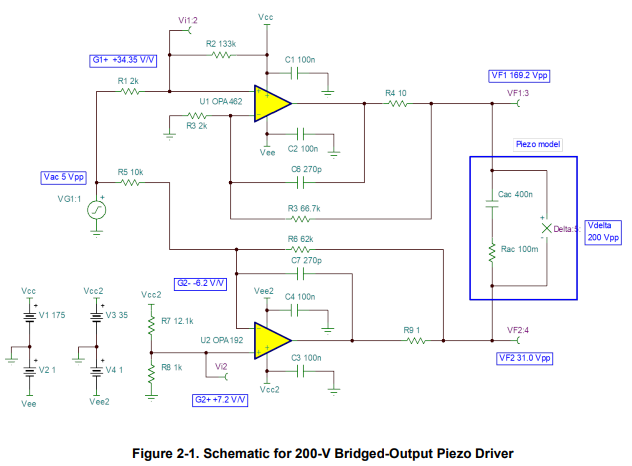

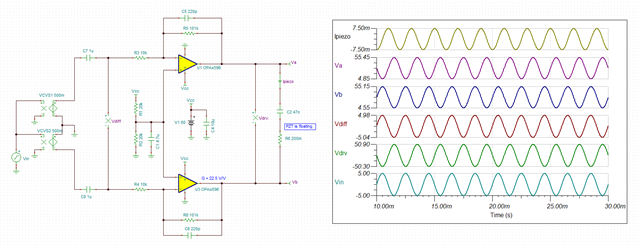

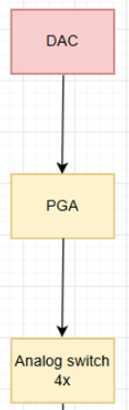

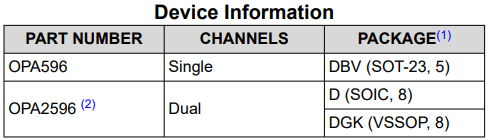

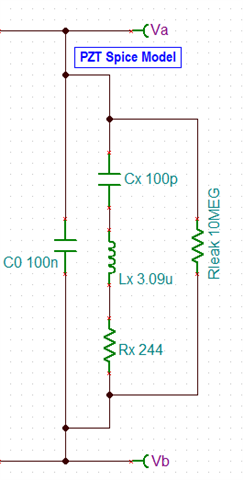

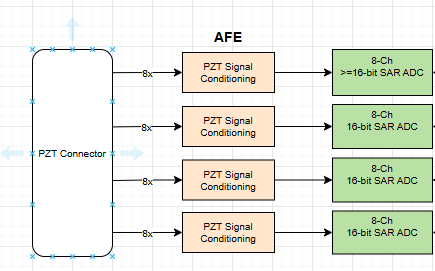

We are designing a data acquisition system that shall comply with the DO-160 military standard. In our system, we will be reading the data from the 32x channel PZT sensor as indicated in the block diagram.

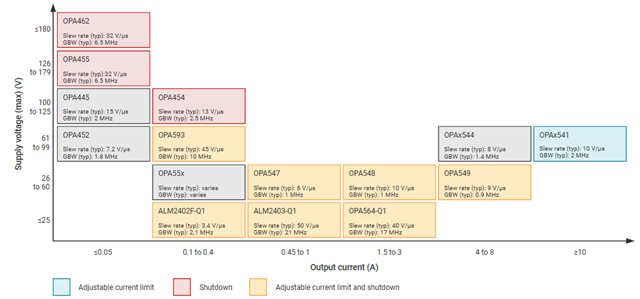

In addition to this, we want to perform impedance/capacitance measurements of each PZT sensor channel by using, maybe, a DAC. Could you please provide a solution for this?

Thanks & Regards,

Sahil Nayak