Hello,

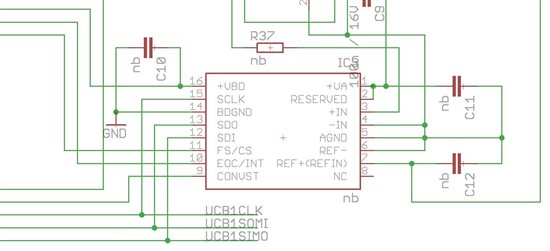

I want to use my MSP430F5437A with an external ADC, therefore I chose the ADS8327 16-bit type, and until now I couldnt find out a easy to understand way to get the data out of this ADC into my MSP430. To be honset I just did start reading the manual and making my first moves on this particular ADC. I am pretty fluent with the MSP430 and C programming, so I have no doubts I will accomplish to read it out someday, but the faster the better.

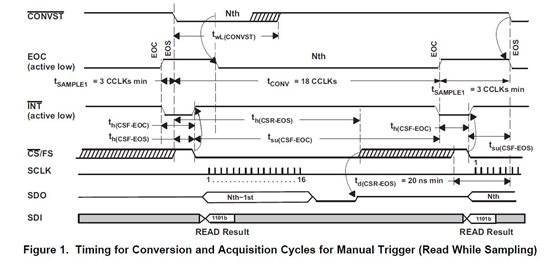

What I did expect to find in the datasheet is some kind of commands, that I could send via SPI and get a response with the 16 bit results afterwards from the ADC. I did already program an external SPI Flash device which was pretty straight forward and easy to understand, but unfortunatly the ADC is not that easy.

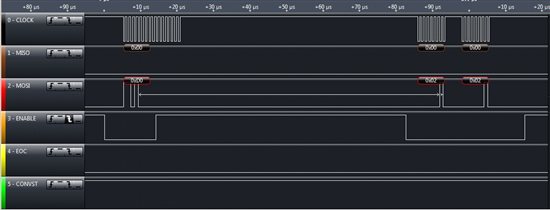

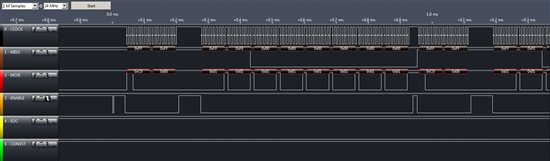

There are some nice figures on page 13 with using the device in manual trigger mode, I think my next step will be to try managing my commands around this figure, although I am confused where I do get my conversion result back? and with what timing.

So if anyone in here already did work with this ADC and wants to share their experiencce with me I really would appreciate this.

I keep this post updated whenever I achieve some goals with the ADC for myselfe, as long as someone seems interested or even responds :D

Greets and thanks for reading,

Seb