Hello, everyone.

I meet some problem right now, that is I can´t obtain the BUSY signal from the ADC.

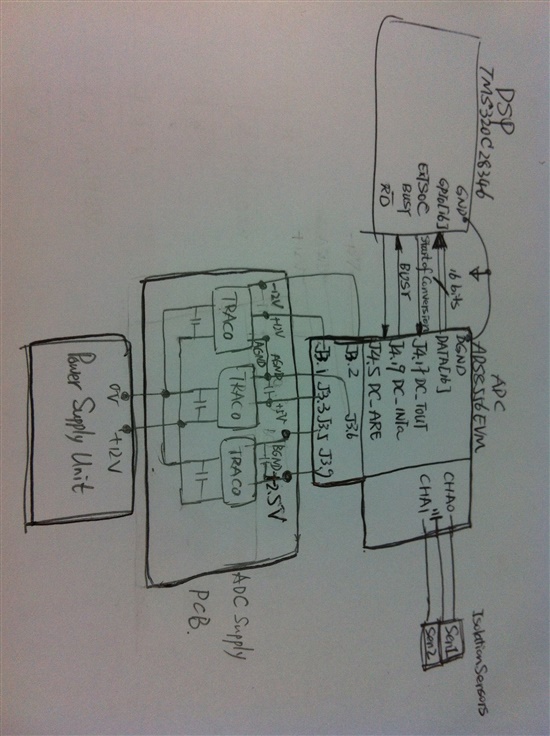

I´m a master student doing my final project right now. I´m using a DSP of TMS320C28346 Experiemnter´s kit to control a AC/DC power rectifier. Since there is no ADC integrated on 28346 control card, we purchased your ADC of ADS8556 EVM. I´ve programmed the external interruption through one GPIO pin of the DSP( this pin later will be connected with the BUSY signal from the ADC),and this external interruption interrupts the CPU precisely.

Now the problem focused on the ADC EVM. I wanna use it in hardware and parallel controlled mode. So that @210kHz, I wanna measure the input voltage of my power rectifier and send the digital 16-bit data all together to the DSP through GPIOs.

Now my testing condition is :

--Analog input channel A0 A1 B0 B1 C0 C1 all connected with the analog ground pins next to them.(just to make things simple)

--A start of conversion PWM signal @ 210KHz is generated from DSP to the ADC to trigger the data conversion.

My configuration is as below:

--For power supply of the ADC board,

I connect +12V to J3.1, -12V to J3.2, +5V to J3.3, and J3.6 connects with the common ground for both +-12V and +5V .

As for the digital supply part, I supply J3.9 with +3.3V and J3.5 with the groud of +3.3V, of course the ground of the former analog part is isolated with the ground of 3.3V part. And also the jumper JP4 is placed to the right, connecting with the 3.3V pin. Rest of the pins in J3 are left unconnected.

For the supply part, I´ve checked all the test points, they are; TP1: -12V, TP2: +12V, TP14: AGND 0V, TP3: +5V, TP8: nothing(because by JP4, .3.3V is connected as BVDD), TP16: +3.3V . Also the diodes D1 & D2 are on perfectly. So I believe the supply part shouldn´t cause any problem.

--For the SW1 part, I did as default in this EVM user´s guide, all the switches turned to the right except for the last one(REFen) to the left.

Of course, JP12 is well placed because I wanna use the internal reference and also I can measure at the TP10 2.5V and TP11 0V perfectly.

--For the other jumpers,

JP1,2,6,7,5,8 are all connected with its Pin2 and Pin3,.Even though in the user´s manual it´s said by default should be Pin1 and Pin2. I´ve ried both ways, none of them worked.

JP10 and 11 are also well placed and I can measure +12V and -12V separately on them.

For JP3, only the first row J1.7 is placed so that /CS signal is connected with J1.7 (tied together with J1.9) in serial control ports. Also I wired J1.9 and J1.10 so that /CS is kept ZERO forever. The rest Y1 Y2 and Y3 are unplaced.

For JP9 I place three jumpers between HOLD A/B/C and DC_TOUT individually. And also I connect the start of conversion signal from DSP to this DC_TOUT in Parallel control ports. Of course I can measure exactly the same start of conversion pulse on HOLD A/B/C since they are tied together.

--For the Parallel Control Ports,

I make DC_A0 and DC_A1 floated HIGH, DC_A2 connected with the digital ground beside it. Thus for the A B C inputs in the U3(multiplexer), I have a HIGH HIGH LOW logic. Plus, for DC_A3, I supply a constant HIGH from one of the DSP GPIO pin, so that G1 in the multiplexer is measured HIGH. For DC_CNTL( connecting with /G2A in multiplexer), I didn´t do anything, and it´s measured LOW. Besides, /G2B is originally LOW. Above all, according to the truth table of the multiplexer, I should have the output Y7 pin HIGH, which gives the /STBY signal to the ADC chip. And I measured Y7 pin from multiplexer, it is HIGH. That means at least I didn´t make the ADC into shut-down mode :P

For the DC_AWE pin, I didn´t do anything either because I don´t want to write at all.

For the DC_ARE# pin, it´s connected with a GPIO pin on DSP so that once the falling edge of the BUSY signal occurs, the DSP jumps into this external interruption and inside the interruption enables this DC_ARE#( /RD in ADC chip )LOW while acquiring conversion data DB[0:15] to a set of 16 GPIO input ports, and toggles HIGH after data acquisition.

In the very end, I measure the DC_INTa(connected with BUSY from ADC chip) and there is nothing but always 0.

Since there is no BUSY pulse from ADC, right now I didn´t connect the DC_INTa with the assigned external interruption GPIO port. Because I think there is no way that DSP would jump into the external interruption with a constant ZERO BUSY signal...

That is pretty much what I´ve done up to now.

Please help me figure out if there is anything wrong with my story or can you please tell me how can I obtain the BUSY signal of the ADC, at least by a simple test to verify that my ADC EVM is not dead.

Thank you so much and looking forward to your reply.

Sisi