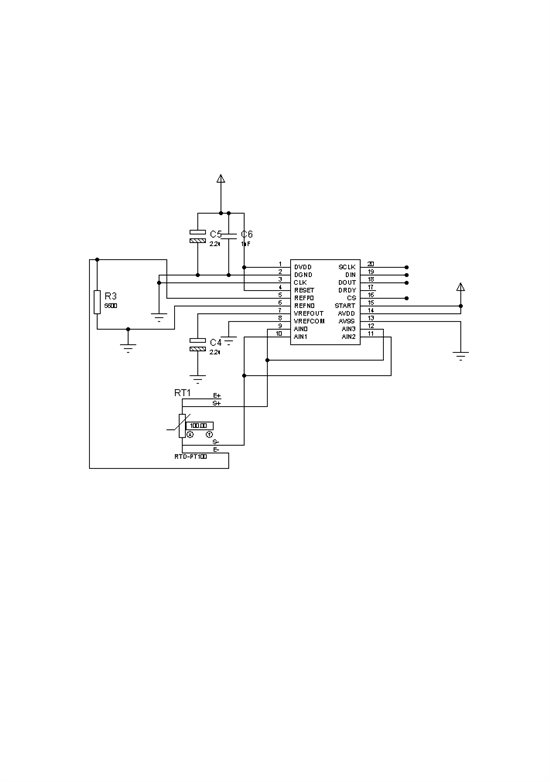

Hello, i am using an ADS1247 to measure the temperature with a Pt100. The hardware configuration is shown in the next picture:

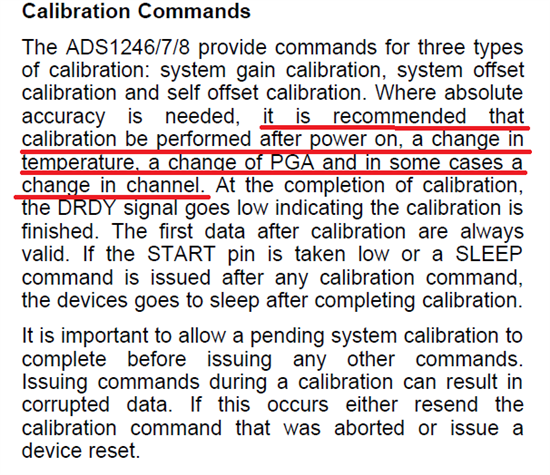

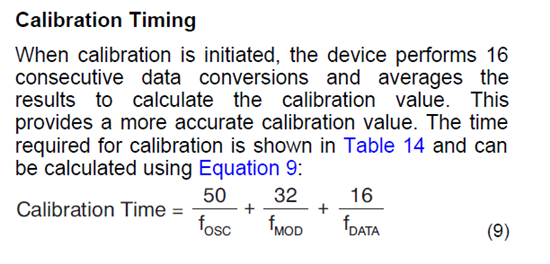

As you can see, i have connected one Pt100 "in parallel" to the 2 entrances (AIN0 AIN1 and AIN2 AIN3) with the intention of control that the 2 chanels are measuring the same temperature. After doing this i could verify that actually this isn´t happening. With the Pt100 expossed to the environment temperature i have a reading of 22.69 °C in chanel 1 and 23.47 °C in chanel 2. My quiestion is how can i correct this error? If the solution is to calibrate the ADS1247, can you explain to me the procedure? I have my doubts in regard with when to use the OFFSET SYSTEM CALIBRATION and the SELF OFFSET CALIBRATION, how should i send the comands of this functions?