Hi all,

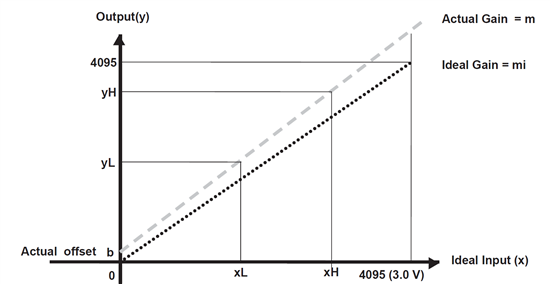

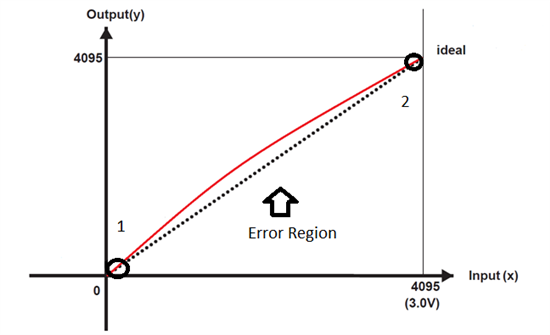

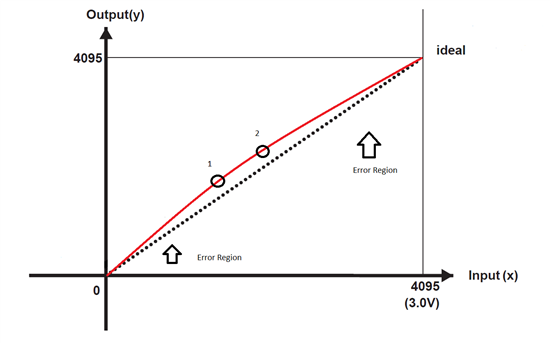

I am using a ADS1147 with a Class A PT-100 RTD with a 4 wire configuration. I have been doing research into correcting gain and offset errors and calculating the offsets I need to refine the measuring accuracy on my system. I have seen a number of resources on using two points to calculate the offsets, but I have yet to see one for a 3 point calculation. Is there such a method out there? and if so, would it be any more accurate over a two point calibration?