Hi,

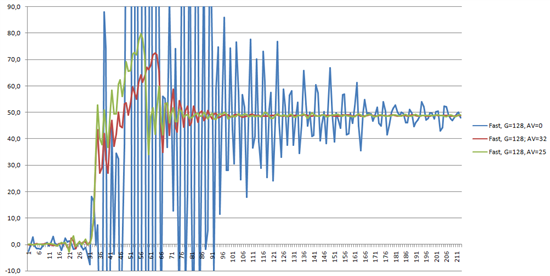

I purchased a REF board for ADS1232. while testing board I figure it out that I have a mechanical vibration around 15hz.

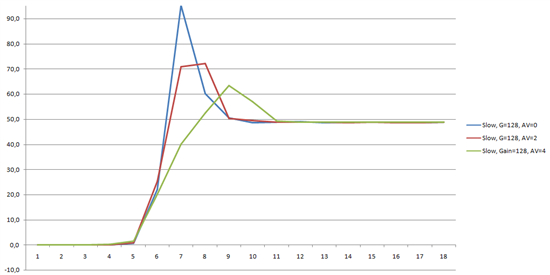

In slow mode I can read weight in 0,7seconds. In fast mode more than 2 seconds. The vibrations are not lineer so I can not average them in fast mode.

Problem is that slow mode is a bit slow for my application. With the help of an external clock I want to downgrade 80sps data rate to a slower rate. and filter out vibration.

1-) If I divide external clock by 8 and use fast mode. Will I get same noise performance with internal clock and slow mode.

2-) How can I set an external clock so that I will have cut off frequency around 6 hz. What is relationship between cut off frequency and external clock.

3-) How will I check 50Hz and 60Hz rejection with that external clock.

4-) how precise should be the external clock. Is there an application note or something that shows an example.

Thanks.