Hello,

I have two question:

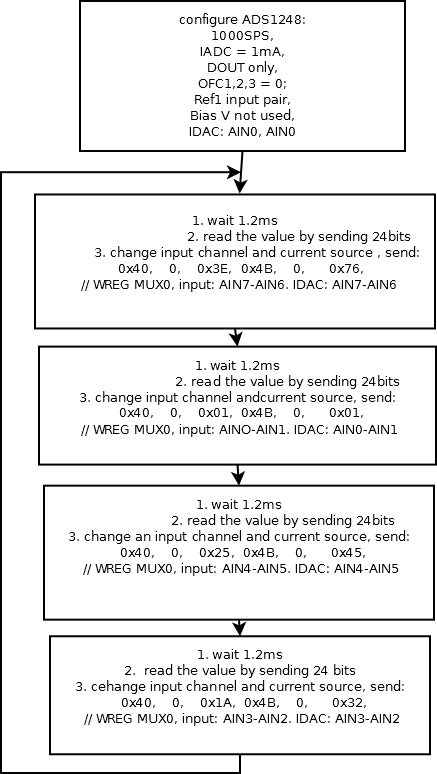

1. I'm reading a room temperature value using one ADS1248 and uC with four three wire PT100.The software multiplex the AINs tofor each PT100 and all PT100 use the same Rref.

The reading seems to be fine until I test puling out a cable of one of PT100 to simulate sensor failure.

Then the values from other, connected, three sensors are all false! After connecting the sensor back the all values are again fine.

Can somebody please explain why is this happening? Are the channels dependant of each other? What is happening to other channels when ADS once read the false value, i.e the value without a sensor input?

2. Can somebody please explain the connection between digital filter reset and conversion time. In particular connection between tables 16 and 15 from the ads1248 documentation, since in my application I'm using multiplexing on 4 channels and therfore changing the MUX0 value, thereby every time reseting the filter according to documentation.

Thank you in advance.