[ ADS1262/3 ] How many sensors can be connected?

Hi expert,

Can you help me to understand input circuit of ADS1262/3 with several sensors?

I'm sorry that I'm not quite familiar with these sensors yet, still studying for my customer.

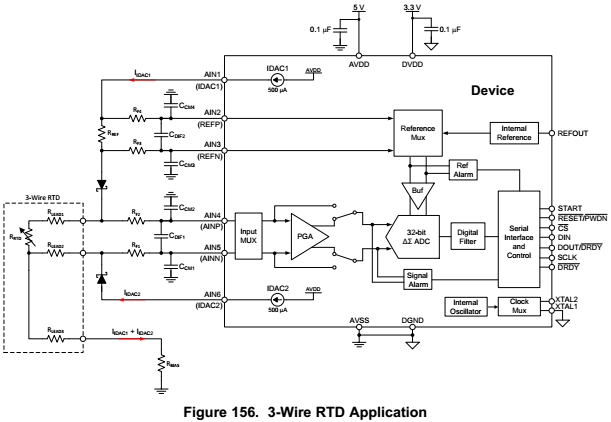

There is a drawing for 3-wire RTD application with lead wire compensation, from this, it seems that 6 analog inputs are already occupied. Does this mean only single 3-wire RTD can be connected with ADS1692/3?

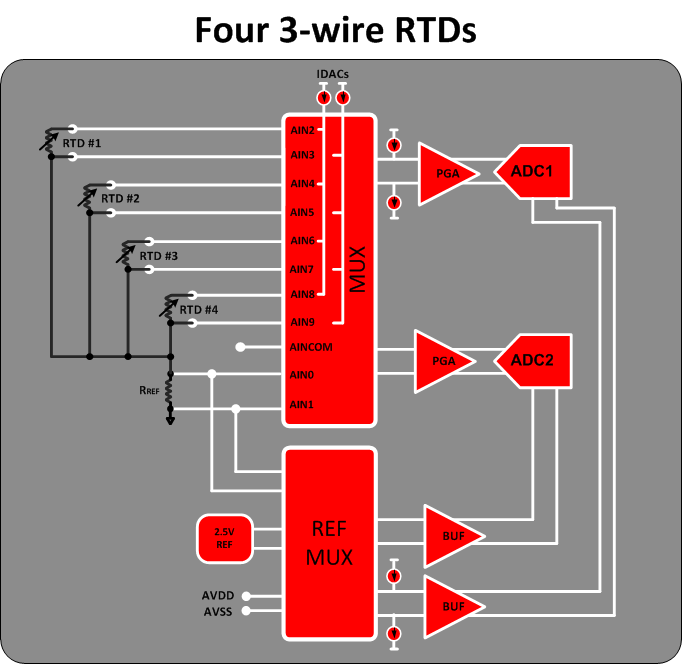

Or AIN4, AIN5 and AIN6 are dedicated for w-wire RTD-1, then AIN7, AIN8 and AIN9 can be used for RTD-2?

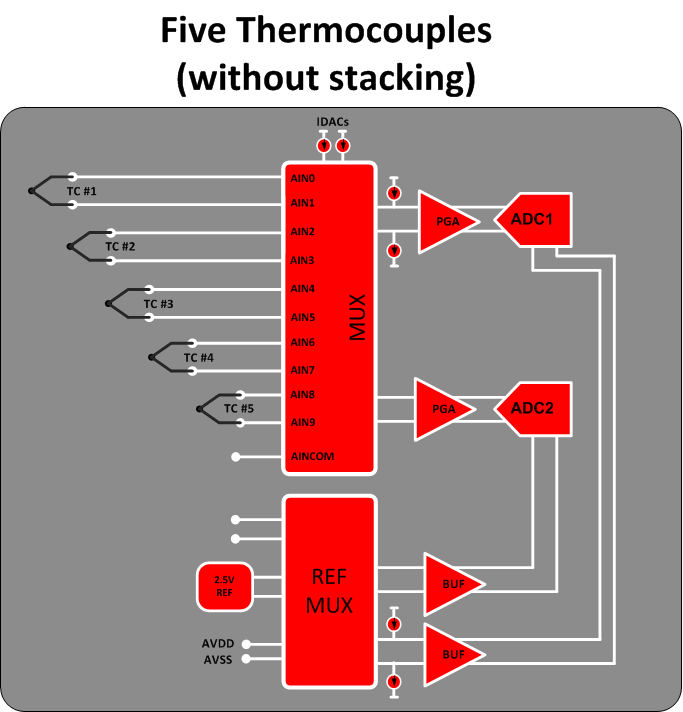

As same as above, how many thermocouples can be connected to ADS1692/3?

My customer would like to use total 12 sensors either RTD or thermocouple. What is the best solution for this?

Thank you for your support in advance.

Thanks,

Ken