We have been using the ADS1258 in a design for about 2 years. We have built around 150 boards. We are seeing about 1 in 20 that have crystal startup problems at room temperature. The crystal never starts oscillating and of course the A/D doesn’t work without a clock. We are doing temperature testing (-40C to 85C) and initial tests indicate that we will have a much higher failure percentage over temperature. So far we have tried the following crystals:

ECS-.327-7-34B-TR 12.5 pF, 50K max ESR, -40C - 85C operating temperature

MC-306 32.7680K-A0 12.5 pF, spec sheet discrepancy - either 35K or 50K max ESR, -40 - 85C operating temperature

We have tried a couple different capacitor values: 12, 22 pF. These seem to give slightly higher than 32.768 KHz crystal frequency. We are measuring the frequency at the CLKIO line and then dividing by 480 to calculate the crystal frequency.

We are assuming that the PLL multiplier is exactly 480, is that correct?

At room temperature, we have seen frequencies in the range below with the crystals and capacitors values above.

CLKIO MHz Crystal KHz

15.728727 32.76818

15.729658 32.77012

We have ordered some smaller capacitors (like 4.7 pF as suggested in the spec sheet) but are concerned that they will cause even higher frequencies. We have also seen where smaller crystals have caused the oscillator to not start as well. The crystal should operate very close to 32.768 KHz when the capacitors are sized properly shouldn't it?

Do you have any other suggestions to allow the crystal oscillator to start up reliably over temperature?

I also noticed that TI makes an ADS1258-EP version of the chip. Does this part have any differences in the crystal drive circuit or is it simply the same as the ADS1258? Would there be any benefit to give this part a try?

The 35K ohm maximum ESR requirement seems to not be easily achievable with standardly available crystals, especially with the -40C to 85C operating temperature. As shown above, we have tried one of your suggested crystals with no luck.

I did notice that the thermal pad on the bottom center of the package is not actually connected to AVss on our board design. There is a pad on the board, but it is electrically floating. Could this contribute to the crystal not starting up?

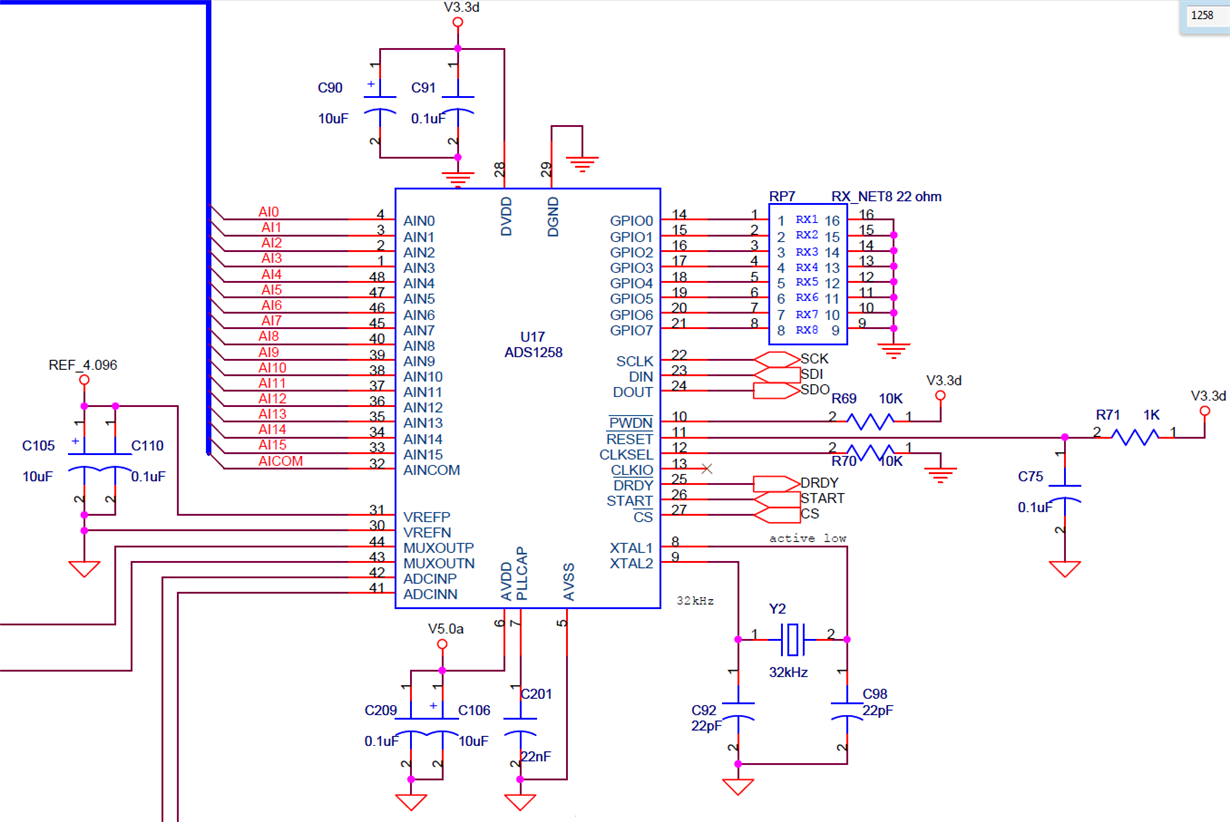

Below is our schematic for your reference. The traces are very short between the IC, crystal and capacitors.

Thanks,

Greg