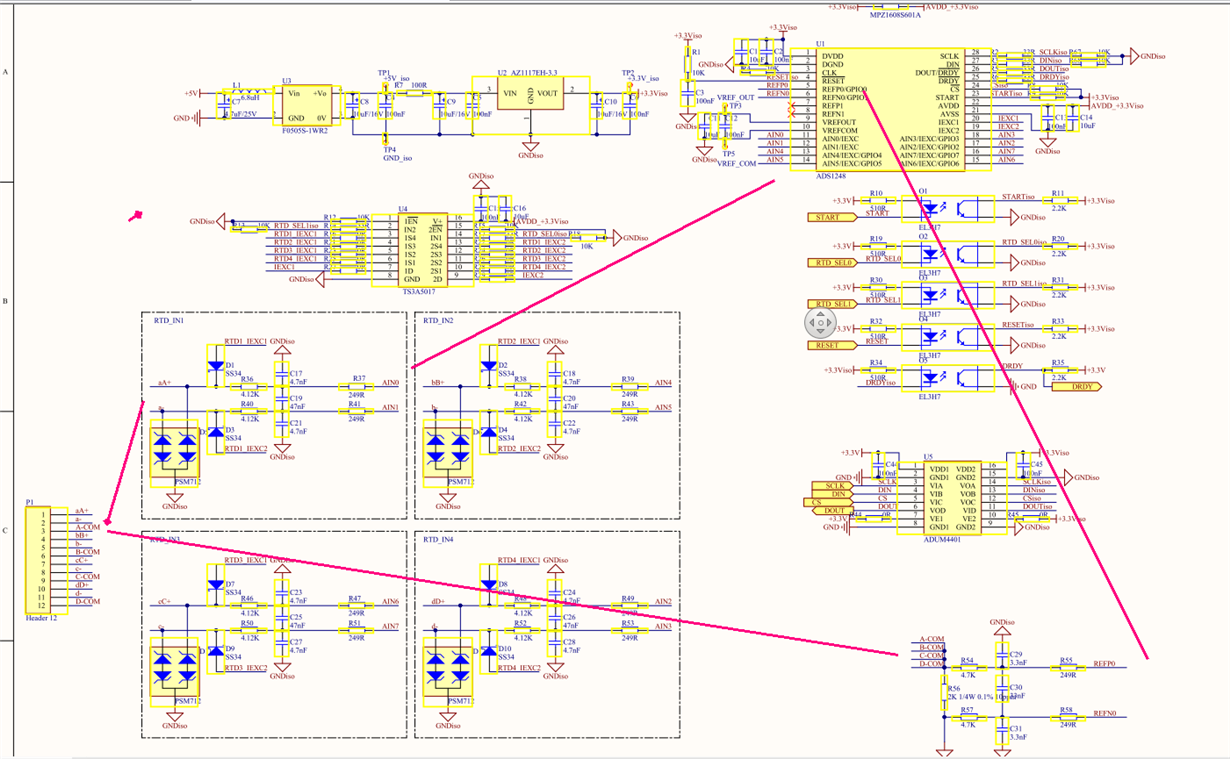

Other Parts Discussed in Thread: ADS1247, TS3A5017, ADS124S08

Hello team,

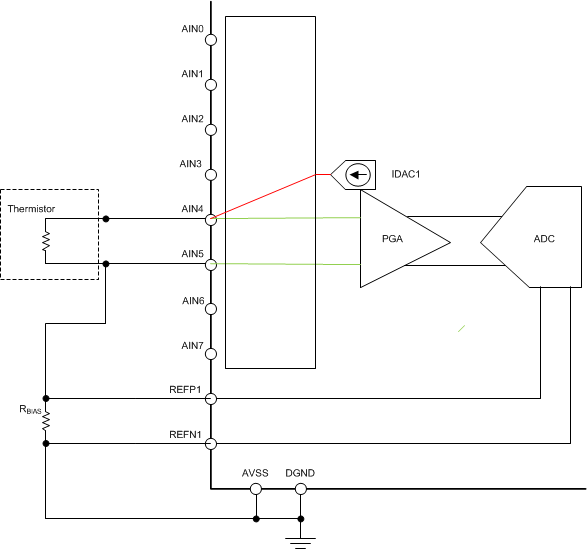

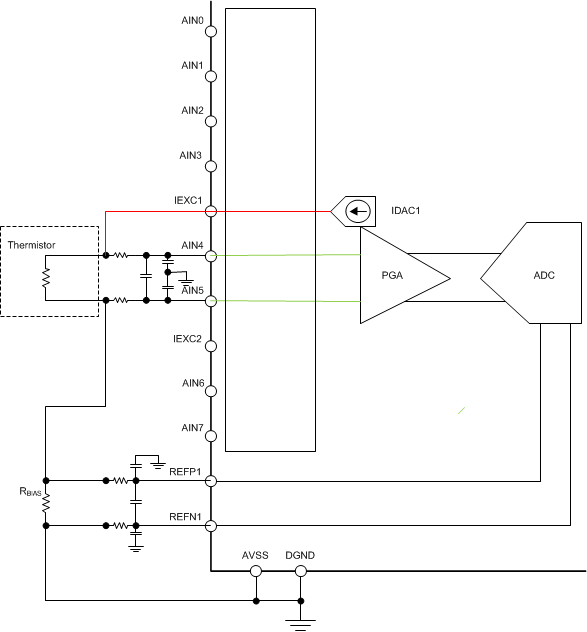

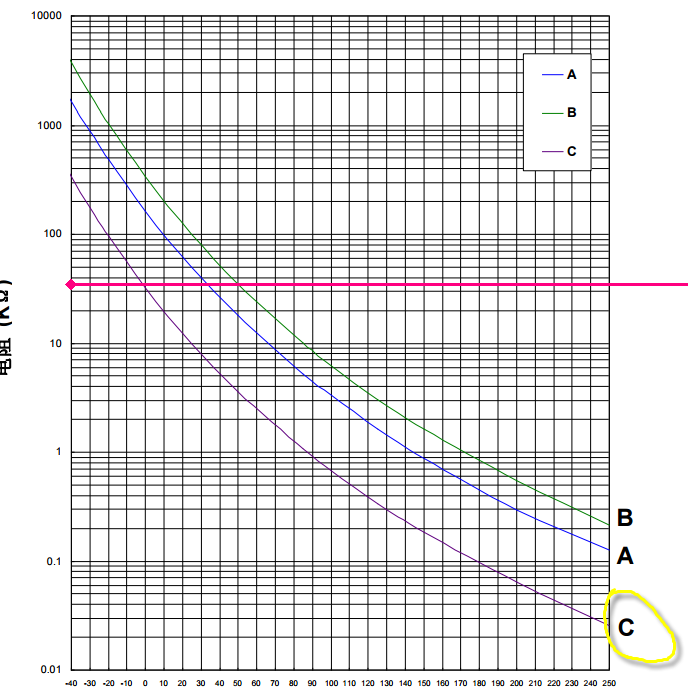

My customer want to find a solution to detect the NTC resistor, which is similar with our ADS1248, Do you have any suggestion about the solution? Below is the datasheet of the NTC resistor, thanks

Regards,

Nanfang