Other Parts Discussed in Thread: ADS1220

Hi

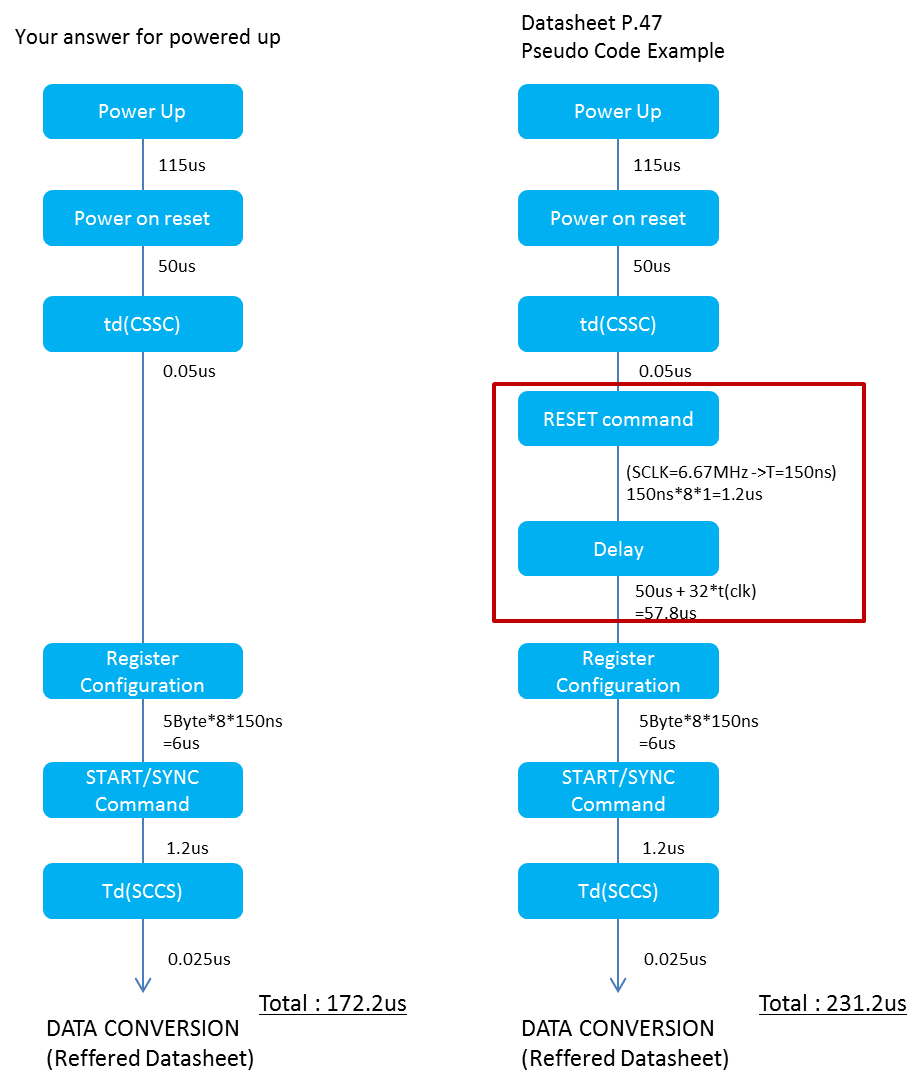

We want to know the minimum time that ADS1120 could work for the following as far as possible.

1. Powered up

2. Reading data

3. Powered down

We want to complete the upper sequence as quickly as possible since we intend to use this device with energy harvesting.

It is OK the data we need is a brief moment data.

How can we estimate minimum time for 1 - 2 - 3 ?

What kind of delay should we consider?

BestRegards