Hi

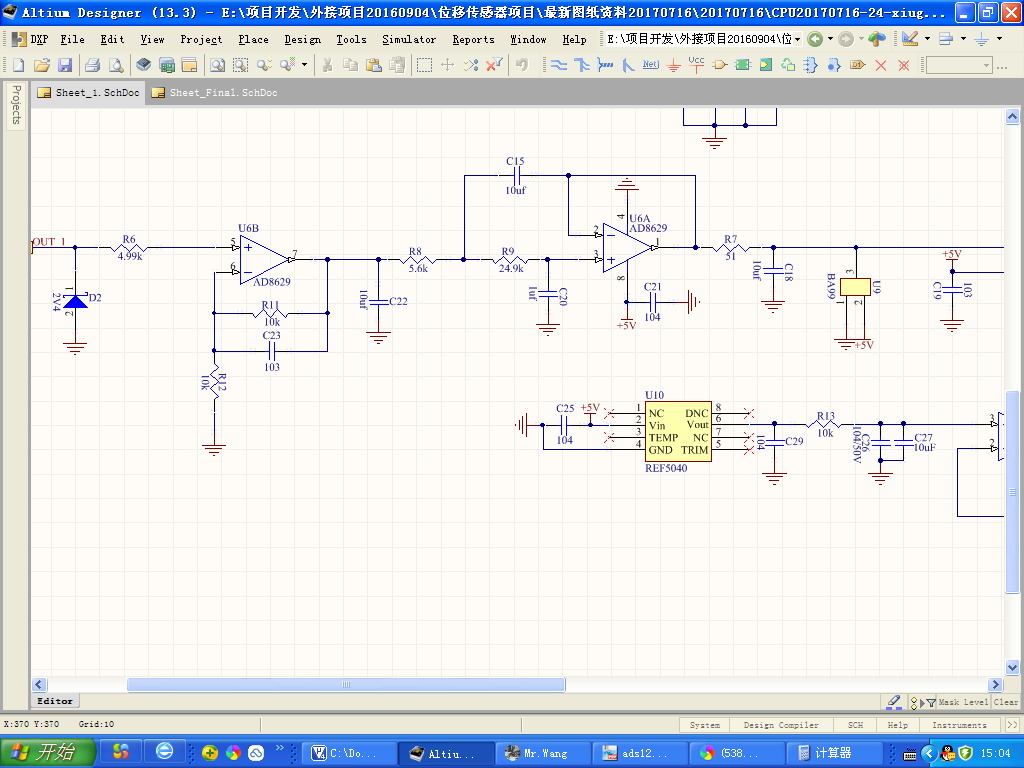

Read the value from ADS1252, the values change in rules. The CLK is 9M.

Please help check the following code:

u32 ADS1252_Red(void)

{

u32 recevice=0,i=0;

while(ADS1252_Out==1);

while(ADS1252_Out==0);

while(ADS1252_Out==1);//t4

while(ADS1252_Out==0);//t2

while(ADS1252_Out==1);//t3

ADS1252_SCLK=0;

for(i=0;i<24;i )

{

recevice<<1;

ADS1252_SCLK=0;

__NOP();

__NOP();

__NOP();

ADS1252_SCKK=1;

Delay_us(1);

if(ADS1252_Out==1)

recevice ;

}

ADS1252_SCLK=0;

Return recevice;

Thanks

Star