Hi,

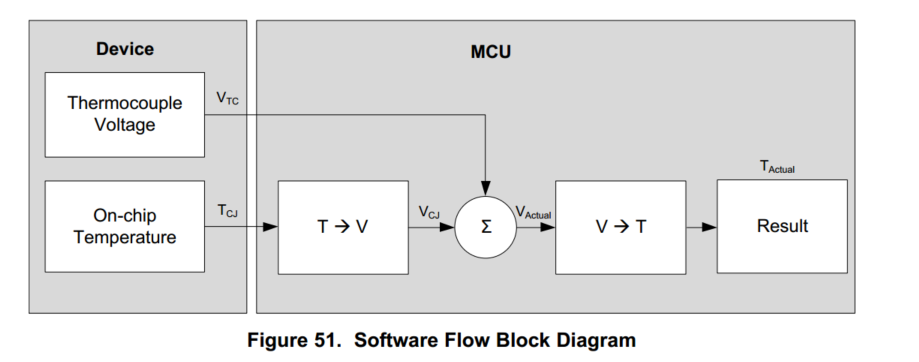

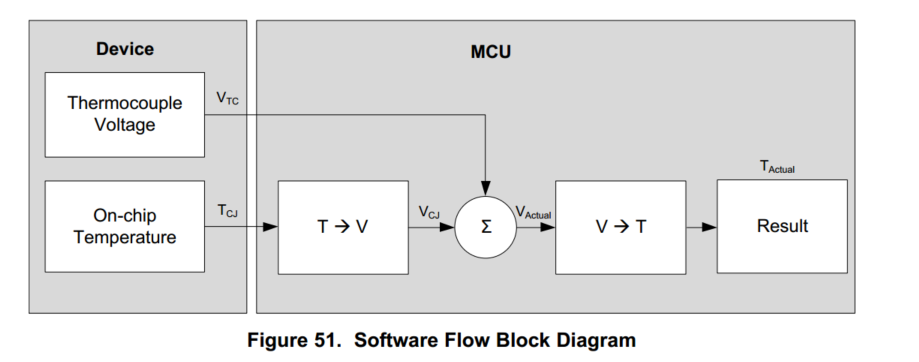

This is Hollis. My customer wants to know why do the cold-junction compensation as below?

Why not convert the Vtc to Ttc directly, then get Tactual by adding Ttc and Tcj? Is there any difference in theory with the below? Thanks.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hi,

This is Hollis. My customer wants to know why do the cold-junction compensation as below?

Why not convert the Vtc to Ttc directly, then get Tactual by adding Ttc and Tcj? Is there any difference in theory with the below? Thanks.

Joachim,

thanks for your reply.

i see there will be some difference between 2 method from your good example. And my question is why the method in datasheet is the right way? is there any standardization organization having some standard process for this?

Thanks.

Please have a look at the following document from Omega (p. 23):

www.omega.com/.../z021-032.pdf

Regards,

Hi Hollis,

I would like to emphasize what Joachim said at the very beginning. Temperature is linear, but the thermocouple is not linear throughout the same temperature region. Adding two temperatures is not the same as adding the voltages and then converting voltage to temperature.

Along with the conversion calculation, the cold-junction area must be accurately measured and isolated from drift sources. As an example, if the ADS1118 is far from the junction of where the TC enters the board, then you may not have an accurate cold-junction measurement. Another example is when air currents flow unevenly across the cold-junction. So board layout is very important for accuracy of the cold-junction measurement.

Best regards,

Bob B