Hello,

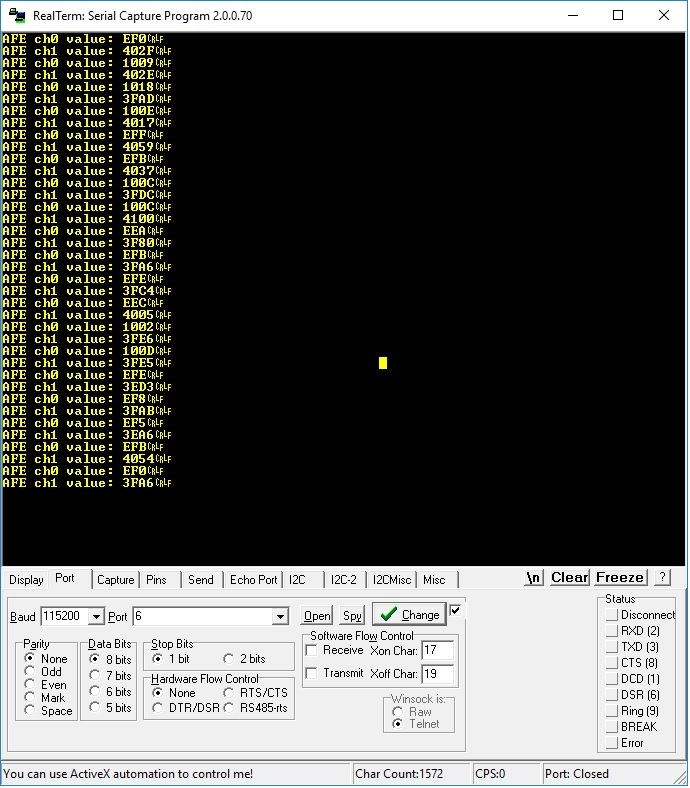

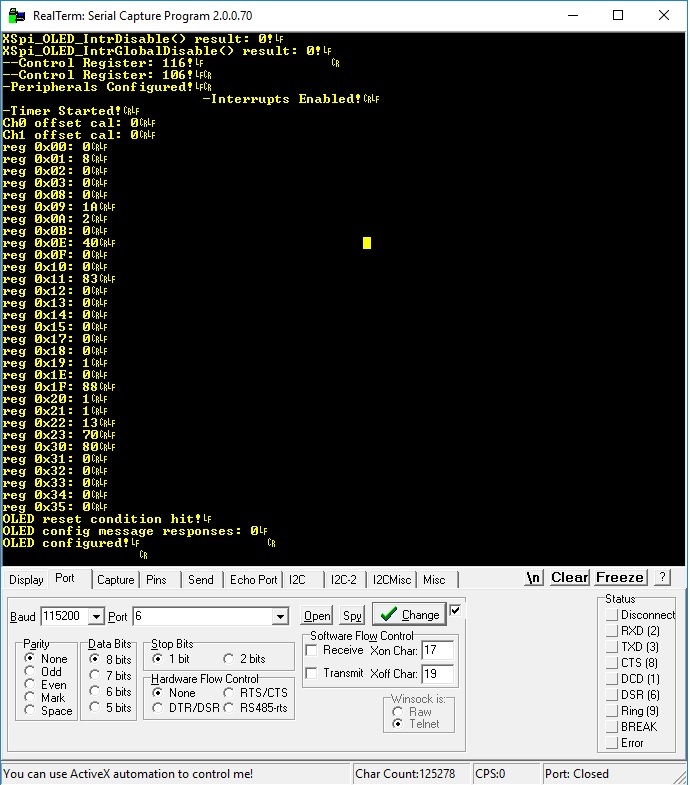

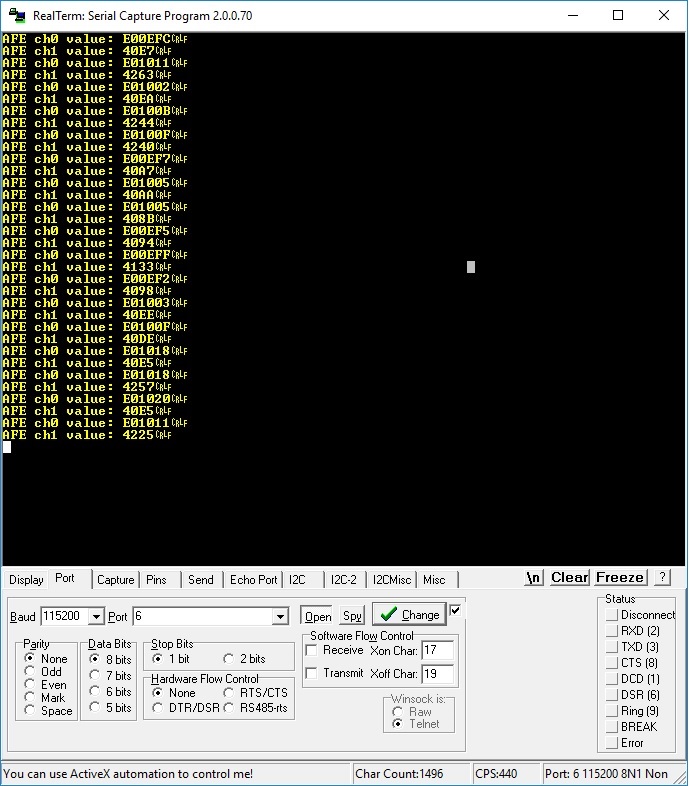

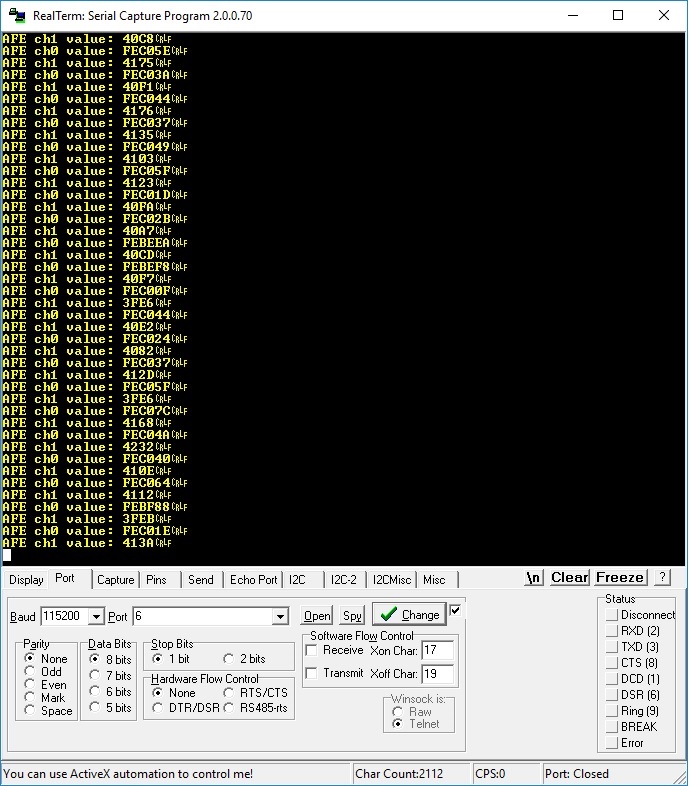

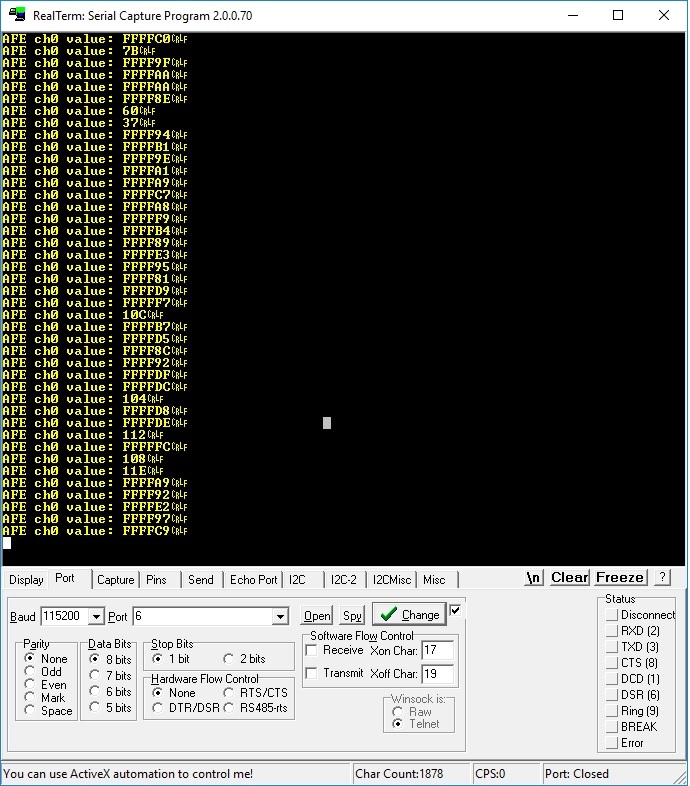

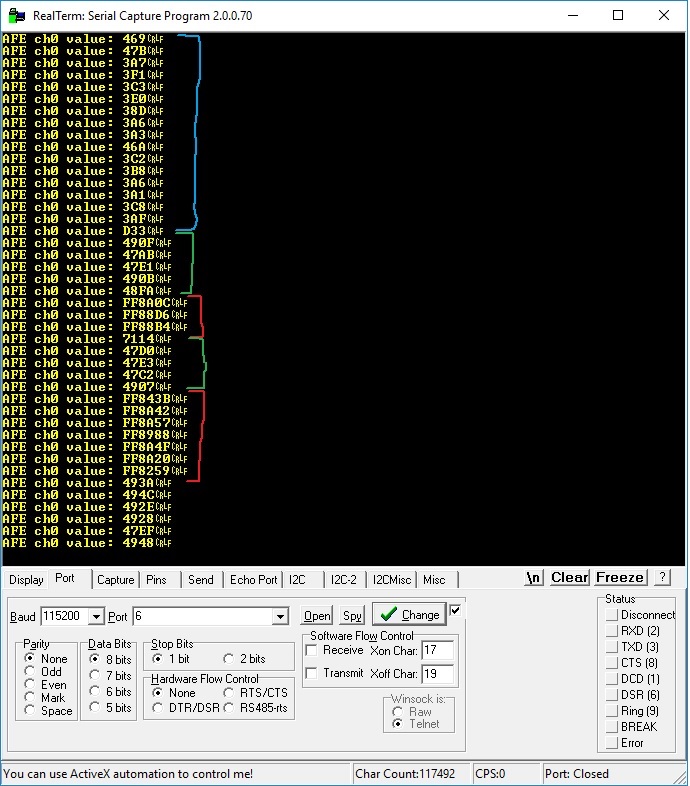

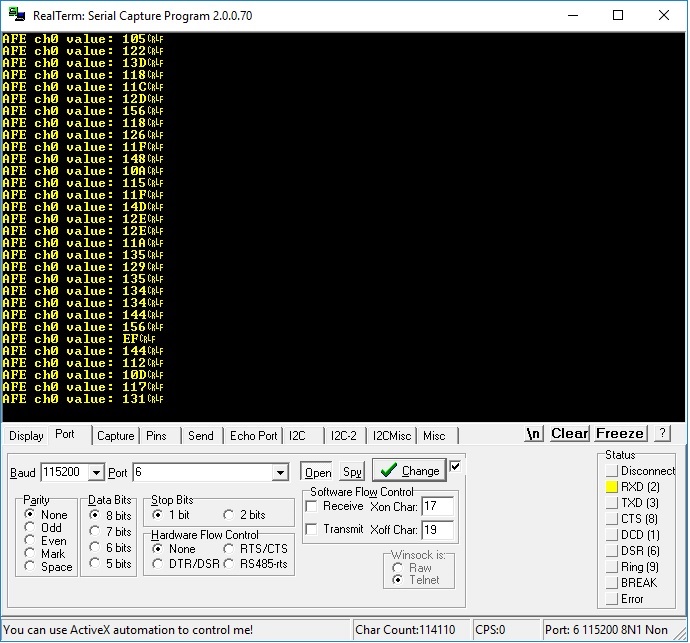

I'm using the LMP90100 in a product and I'm having a difficult time zeroing out the input. Input channel 0 is connected to a strain gauge and when I power up the system I'm measuring roughly 0xF98. Obviously this moves around but that is say my average value. I'm trying to zero out the input as best as I can. The strain gauge will have a range of +/-5mV. I plan on using the gain available from the FGA and PGA, but if I use the gains without zeroing out the input (or getting as realistically close to zero as I can) my readings blow up because I'm amplifying this DC offset.

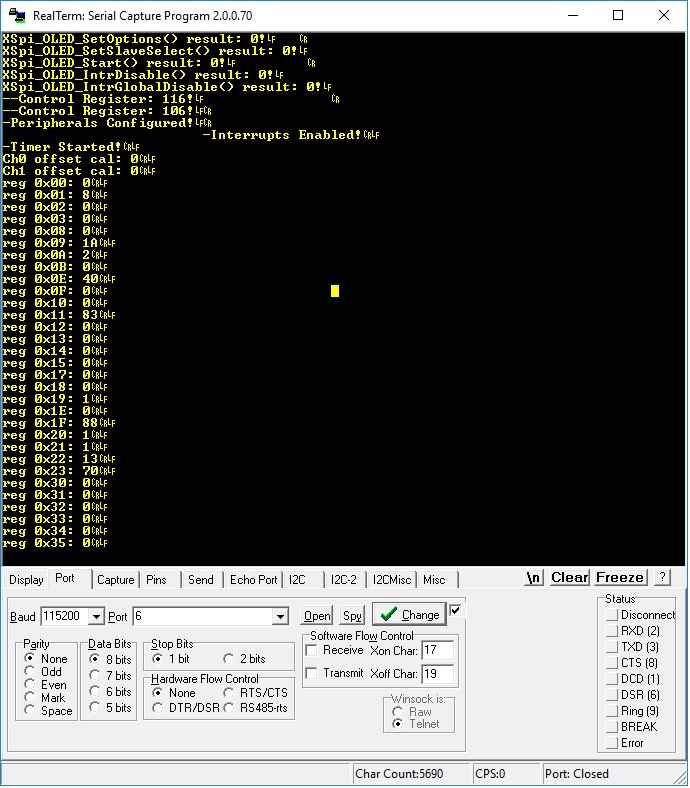

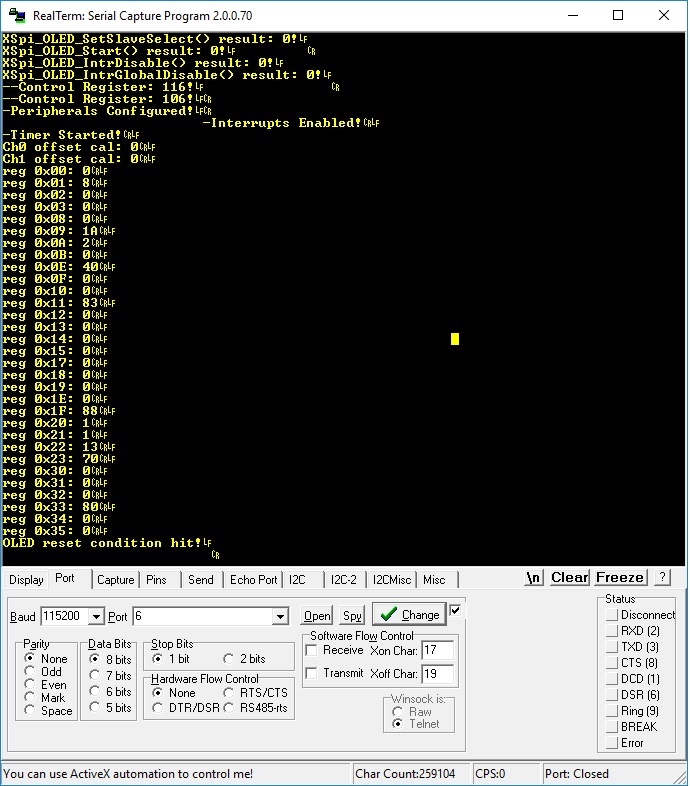

I've tried to use the "system calibration" from 9.3.7.2 of the datasheet, but when I set the CH0_SCAL_OFFSET register with ~0xF98, which is what my offset looks to be) I get ~0x1000 hex as my steady state offset. From the data sheet I thought whatever you loaded into CH0_SCAL_OFFSET was just subtracted from your ADC sample. All I would like to do with the embedded system is check x number of samples at power up, average them and then subtract them using the CH0_SCAL_OFFSET register. I've read through the data sheet over and over and it seems like this should be the approach that I take, but I can't get the input to approach zero.

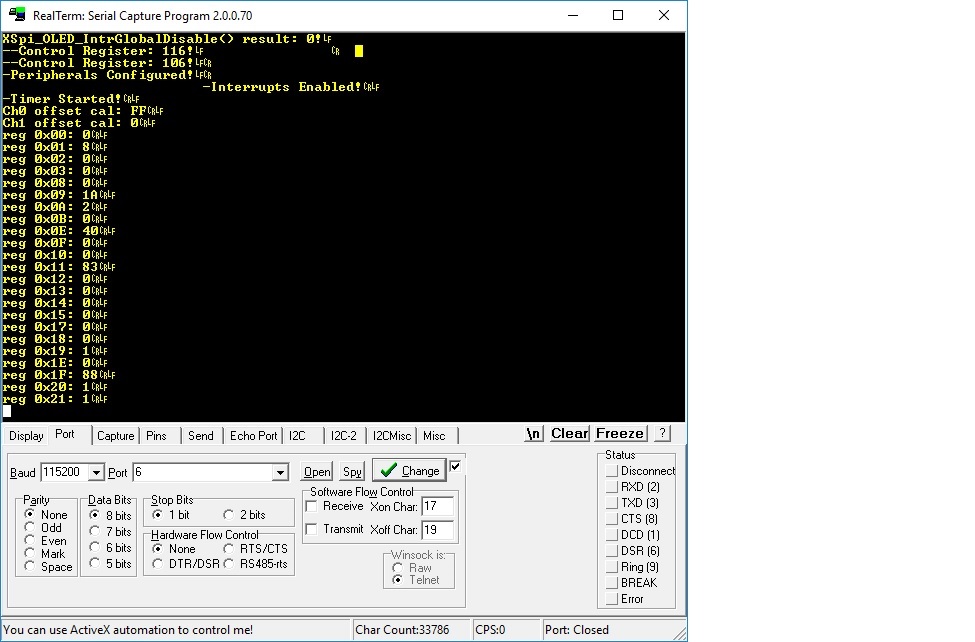

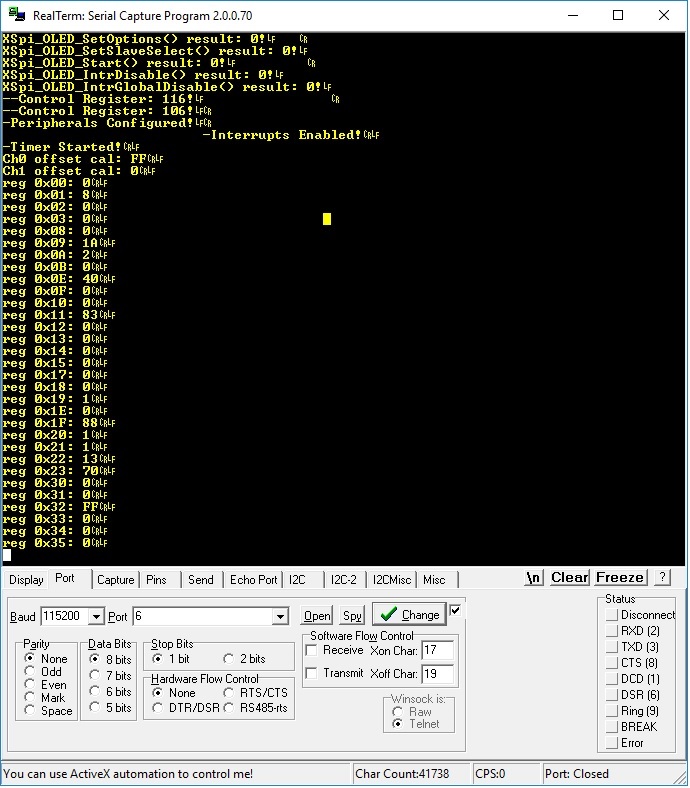

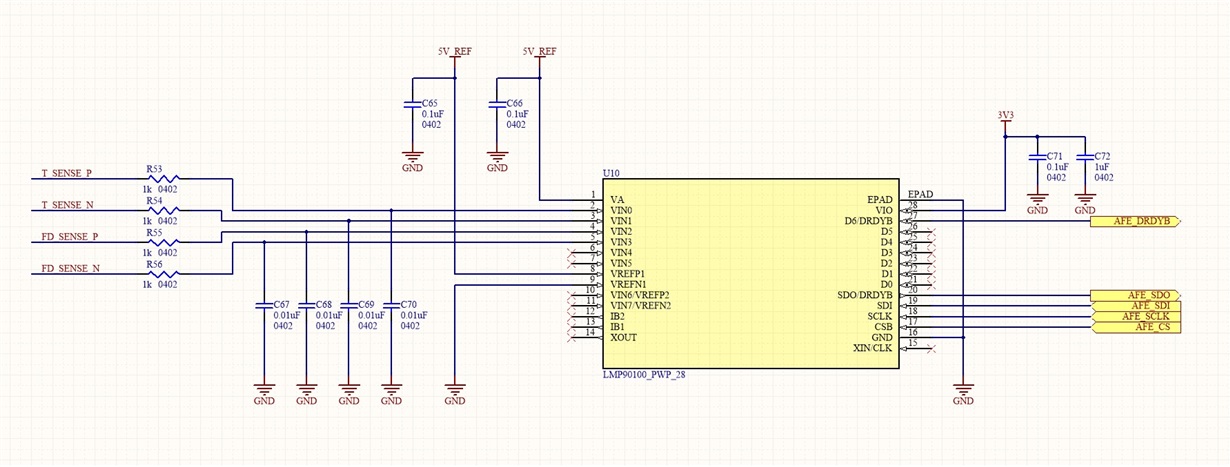

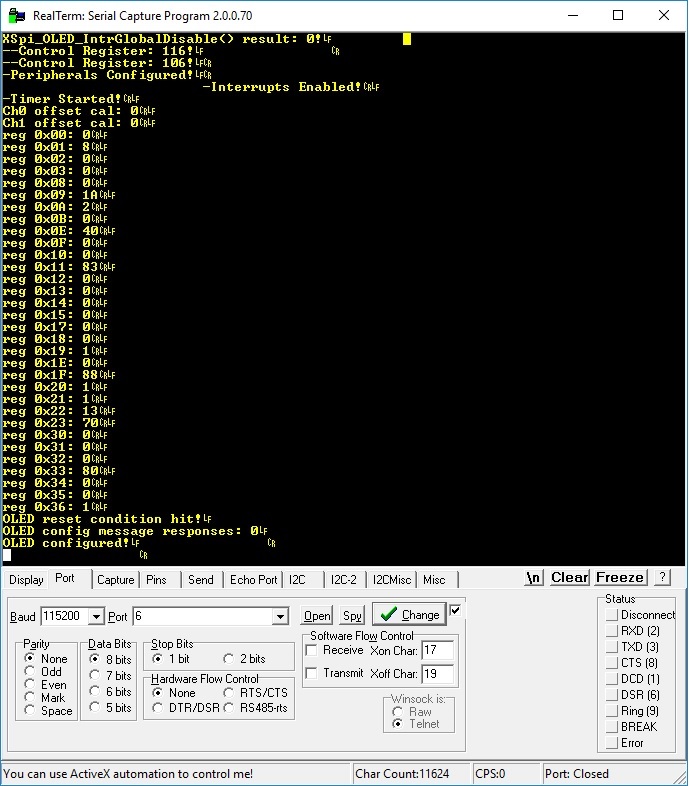

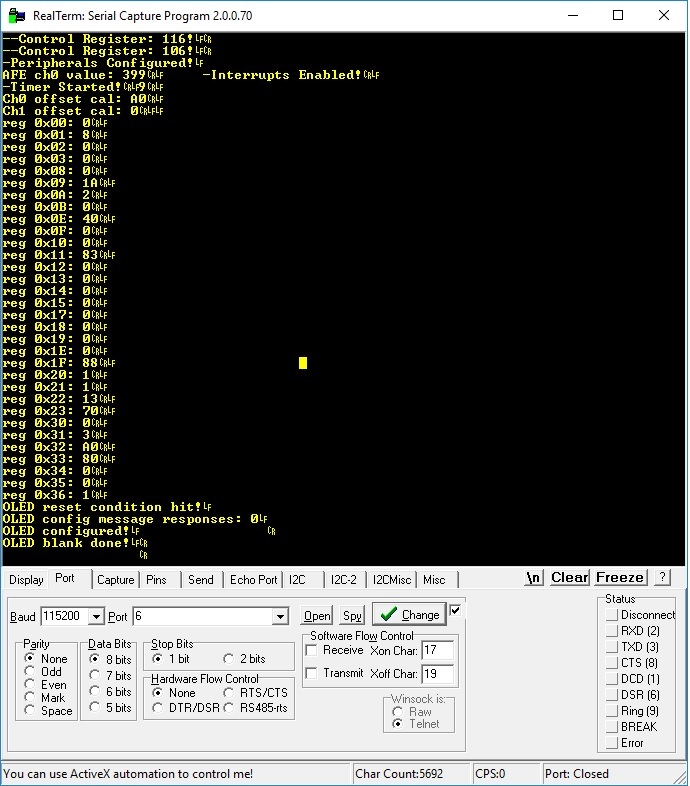

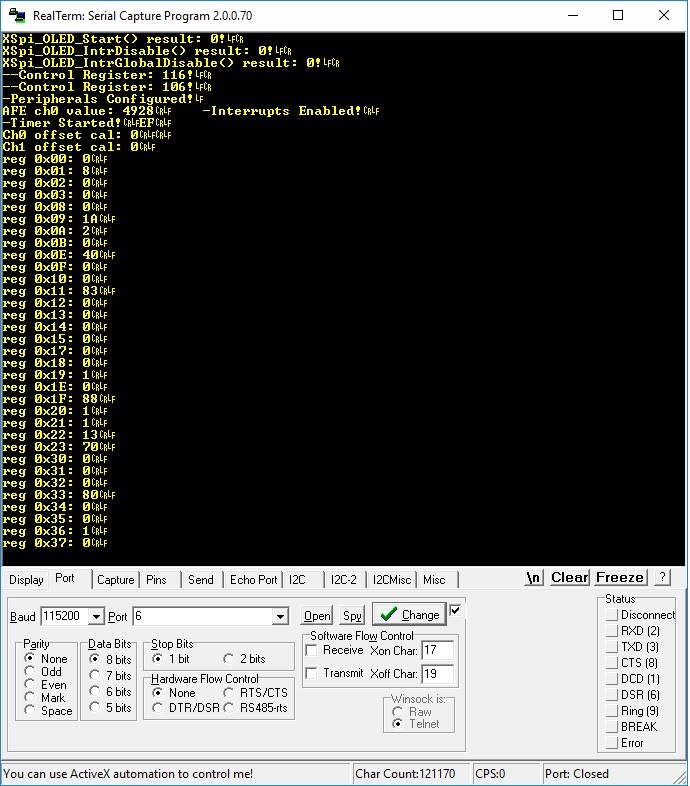

The lmp90100 is currently configured for 2x channel mode at 214sps with no gain. channel 0 consists of VIN0+ and VIN1-. Channel two is VIN2+, VIN3-. I am not using any gains at the moment as I'm just trying to bring the offset down and I AM using the current buffer. The ADC analog power is connected to a 5V high precision reference from TI as well as the strain gauge (resistive bridge). For this testing though, I'm just driving the inputs for channel 0 with a high quality power supply. I'm driving 2.00V into both the + and - of channel 0 and measuring the very small mismatch. I can see the ADC functioning when I change the differential voltage between the inputs. One direction increases with positive numbers and the other direction increases the signed output so it looks like the device is working fine.

Am I missing something?

Thanks!