Hi all,

This is my first question on the TI forum, so maybe I will break some rules ?LOL

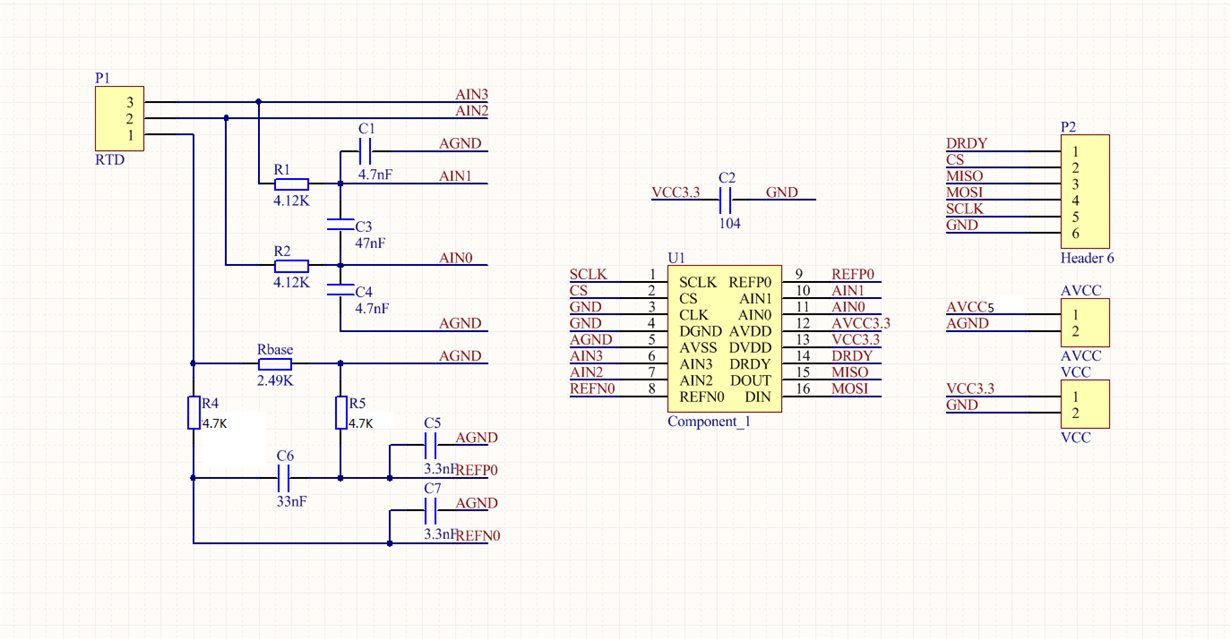

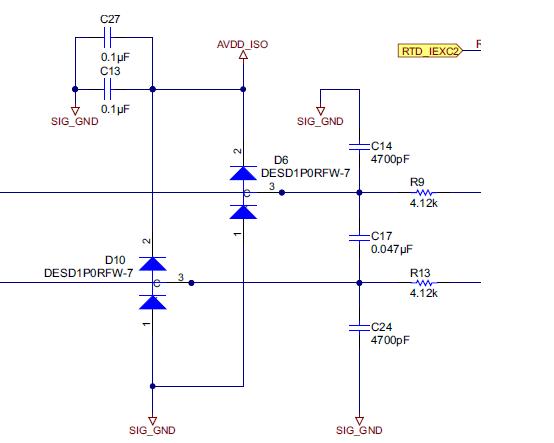

Here is my Circuit schematic , I have combined the design of the datasheet ADS1220 and the design shown on figure40 page 33 of TIDU271

The compoments selected for the fliters of VIN and VREF are based on the data shown on page37,38 of TIDU271

The SPI channel is connected to a MCU STM32F103.

The registre setting is 66h 04h 55h 70h .

I can change the value of VREF(mesuring by a voltmetre) by changing the registre setting(value of IDC), I think it means the SPI connection works well.

The MCU can receive the 24 bits data converted by ADS1220.

There are 3 problems

1 : figure40 page 33 of TIDU271 shows that we can supply VDCC of ADS1220 by 5 volts , but in fact , the SPI connection will never work while using 5v VDCC , it only works on 3.3v VDCC.

2 : When the MCU restart , the 24 bits data received will be "abnormal" ,always 0x7FFFFF or 0x800000. To return "normal" data , il takes a while to wait or I can disconnect the PT100 and reconnect it.

3. The offset is not stable , here is the table I have mesured with a calibrated temperture equipment (the calibration of this equipment maybe not good enough to provide a well temperture)

| Temperture | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 |

| Standard | 1608995.65 | 1660742.25 | 1712488.84 | 1763965.92 | 1815308.25 | 1866515.81 | 1917453.87 | 1968391.92 | 2019060.46 | 2069594.24 | 2120128.03 |

| Mesure | 1551952 | 1602620 | 1652042 | 1702369 | 1751886 | 1801365 | 1851184 | 1900589 | 1950509 | 1997712 | 2046000 |

| Offset | 57043.6549 | 58122.2489 | 60446.8428 | 61596.9232 | 63422.2469 | 65150.8138 | 66269.8672 | 67802.9206 | 68551.4605 | 71882.2436 | 74128.0267 |

Design of 3 wines RTD in datasheet of ADS1220 shows that it only needs a offset calibration when PT100=100 ohms ,but the data shows that the offset will increase when the 24bits data increase.

The 24-bits data received by the MCU is also unstable,the data will change randomly(with a offset about 5-6 degrees) while light touching the circuit(like the pins of PT100).

Cordialement

SITU