I'm using the LDC1612, attached to the TMS320F28069M C2000 MC. Over the current range I'm running my test using the LDC1612, I need to adjust the DRIVE_CURRENT_CH1 register twice to avoid getting data error codes.

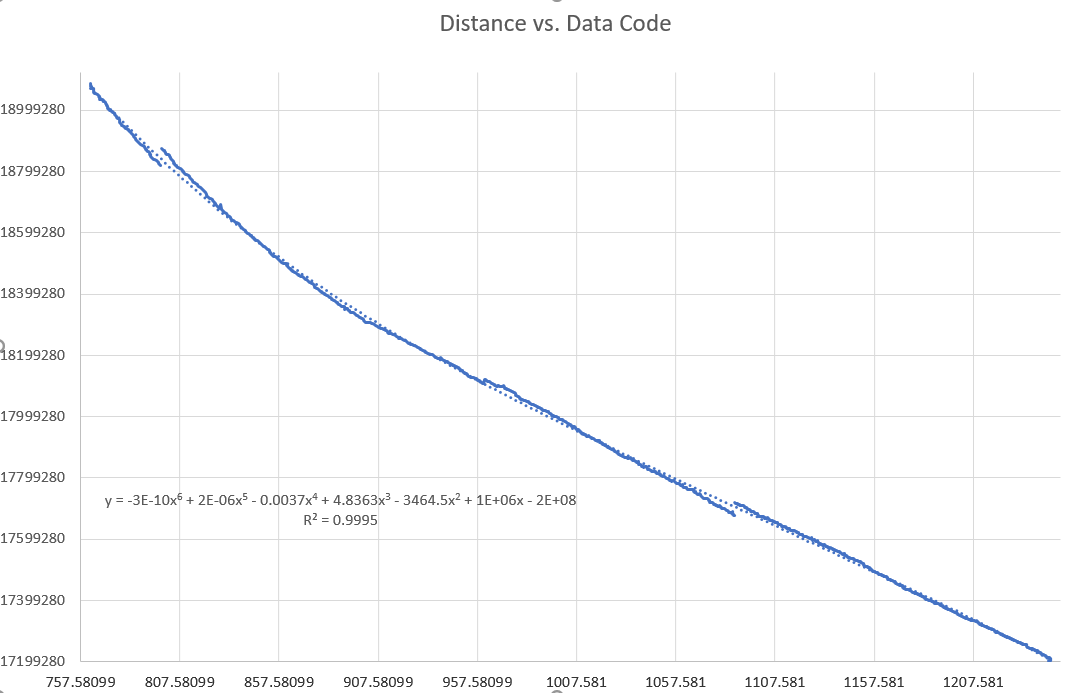

Simple enough, when the DATA_MSB_CH1 register returns an error code, I adjust the DRIVE_CURRENT_CH1 register to one value lower, which fixes the error code. My problem is that when I do this the data resulting from DATA_MSB_CH1 and DATA_MSB_CH0 returns large discontinuities that make mapping the output codes to a distance quite difficult. Here's a graph of this problem (so it is more evident): \

\

The two discontinuities are fairly evident, but they occur at ~1075 and ~775 microns.

So my question is fairly simple, how do I avoid this type of problem? I take approximately 50 samples for each report, so it is not simply a single weird data code. But I assume I do need to adjust the drive current to avoid damaging the sensor with voltages that are too high. Yet I'd like to avoid these jumps.

Thanks in advanced!