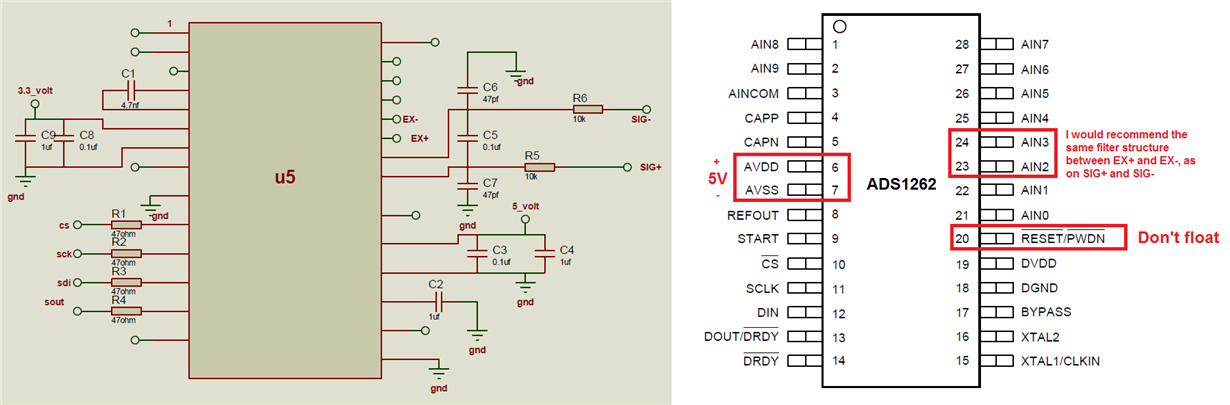

we are evaluating ADS1262 for accurate weighing measurement, we are getting accurate result but last 2 or 3 digits fluctuating after 300,000 counts and taking time to get it stable so it seems like we are facing some noise issue, can you please recommend us a proper schematic or any change required in PCB layout? we are referring TICD188 for this.