Other Parts Discussed in Thread: TVS0500

Hi Team,

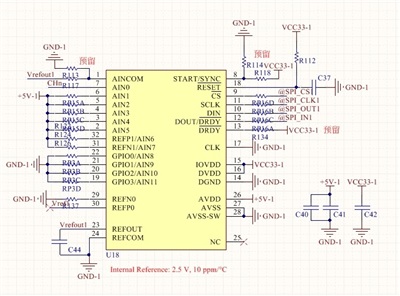

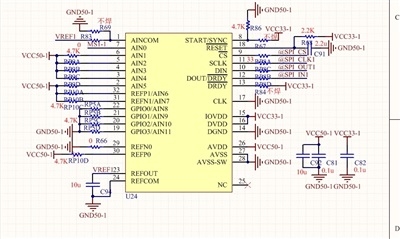

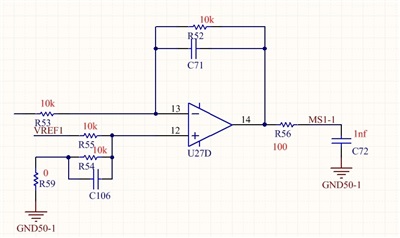

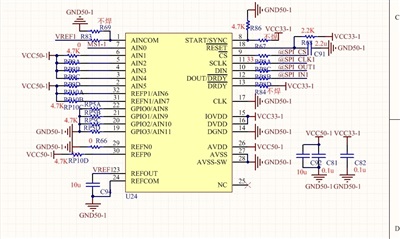

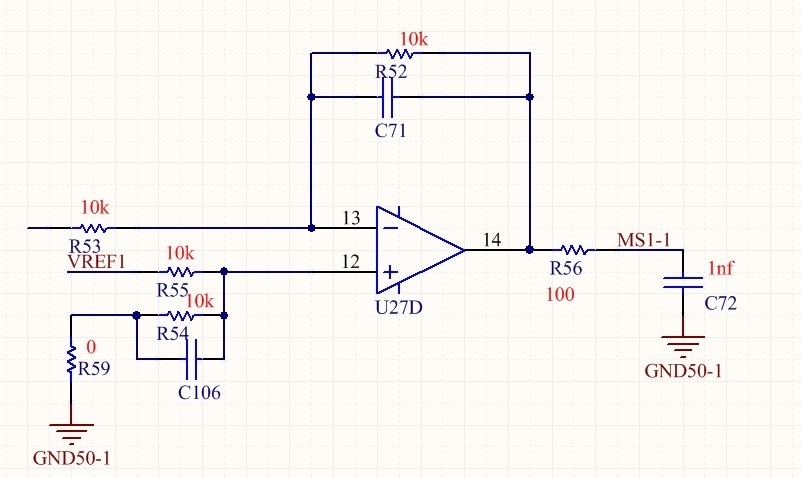

My customer is using our ADS124S08 in their project. When they doing the ESD test, ADS124S08 was found abnormal status. Firstly, pls find the schematic from below:

Start pin is pulled low, R114 installed and R118 uninstalled. For the PCB, Analog GND and Digital GND are using a single plane, this should be helpful for EMC test.

During ESD test, +/-8.8kV contact discharge test on equipment, sometimes ADS124S08 will stop to output data normally. It was found ADS124S08's DOUT/DRDY pin will always high(busy status) and never low. We tried below:

1. If we try to read data from ADS124S08, all output 0.

2. Also we tried to send stop command and send start command again, it seems ADS124S08 is still in the wrong working status and still output 0.

3. We tried to read all the registers back from ADS124S08, all registers are correct and same with our initial value. This verify that ADS124S08's SPI interface is no problem, SPI communication is still good even in this abnormal status. Below are the registers:

| Register Address | Value |

| 00h | 08 |

| 01h | 00 |

| 02h | 0C |

| 03h | e8 |

| 04h | 1a |

| 05h | 0a |

| 06h | 00 |

| 07h | ff |

| 08h | 00 |

| 09h | 11 |

| 0Ah | 00 |

| 0Bh | 00 |

| 0Ch | 00 |

| 0Dh | 00 |

| 0Eh | 00 |

| 0Fh | 40 |

| 10h | 00 |

| 11h | 00 |

4. If we want to escape from this abnormal status, we have to reset the ADS124S08 but the reset pin, after reset ADS124S08 and re-initial the ADS124S08, ADS124S08 will go back to normal status.

So based on above test, it seems the ESD noise makes part of ADS124S08's digital circuit abnormal, maybe the conversion part, Now customer is planning to do pp, it is very urgent to solve and explain this issue, need application or design experts' support on this case! Can experts give help supporting this issue? Thanks a lot!

Best regards,

Sulyn