Hello,

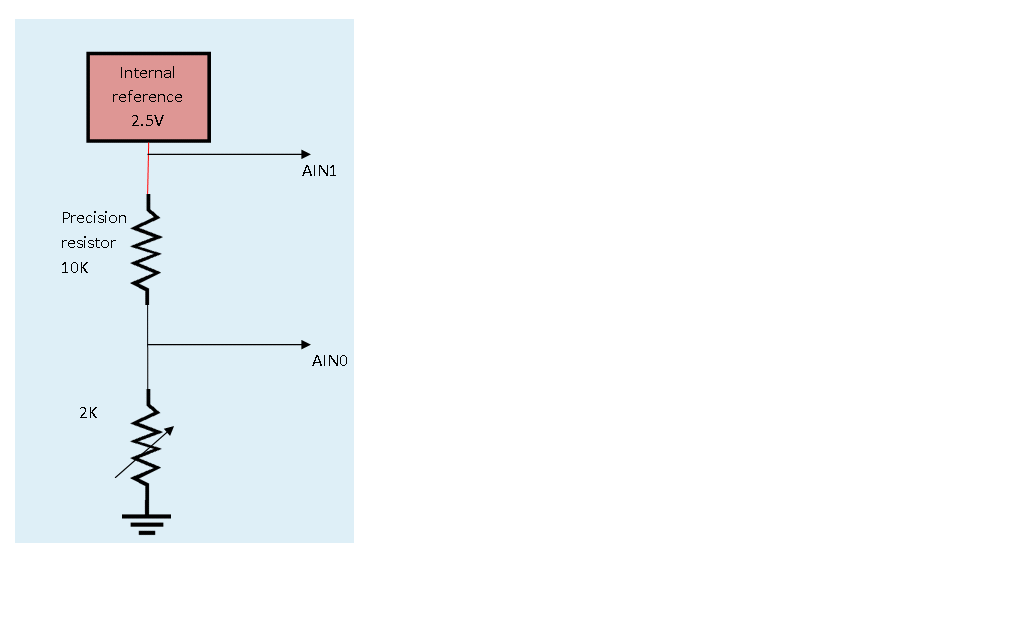

we are using ADS124S06 in differential configuration, using ADC internal 2.5V reference. The input to ADC comes from the voltage divider as follows:

AIN1=2.5V internal reference

AIN0=signal=0.4166V (signal from divider with 10K and 2K precision resistor)

We are however not getting the correct value in differential mode measurement. The configuration that we have kept for register settings are:

( STATUS_ADDR_MASK, 0x80 );

( INPMUX_ADDR_MASK, 0x10 );

( PGA_ADDR_MASK, 0x00 );

( DATARATE_ADDR_MASK, 0x81 );

( REF_ADDR_MASK, 0x3A );

( IDACMAG_ADDR_MASK, 0x00 );

( IDACMUX_ADDR_MASK, 0xFF );

( VBIAS_ADDR_MASK, 0x00 );

( SYS_ADDR_MASK, 0x10 );

( OFCAL0_ADDR_MASK, 0x00 );

( OFCAL1_ADDR_MASK, 0x00 );

( OFCAL2_ADDR_MASK, 0x00 );

( FSCAL0_ADDR_MASK, 0x00 );

( FSCAL1_ADDR_MASK, 0x00 );

( FSCAL2_ADDR_MASK, 0x40 );

( GPIODAT_ADDR_MASK, 0x00 );

( GPIOCON_ADDR_MASK, 0x00 );

Please update whether these settings are correct or not for doing differential measurement.

As per above figure, we should get 0.41 V in measurement while the ADC counts (6990303) that we are getting is close to 1.04 V,

The required figure of 0.41 V can be get if we subtract the twice of 1.04 V (1.04 V * 2 = 2.08 V) counts from 2.5 V. Please suggest the correct method for computing final vale in differential measurement.

Please support for possible mistake in register settings, do let us know for any clarifications needed for the specified problem.

Regards

Prateek