Hi

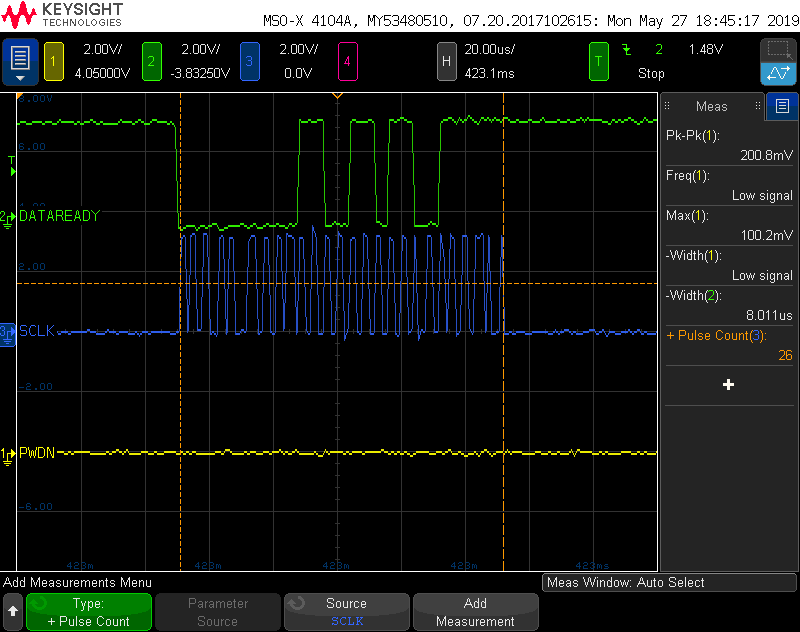

we are using ADS 1234 in our design for a load cell weight measurement system. The ADC works is working fine but in some power up the device is reading constant value 7FFF irrespective of the input variation.This issue is causing lot of trouble in our system.Please help us on this.The powerdown pin recommendation is followed in the firmware.Please share any other fix that could solve the issue

Thanks

Abin