Part Number: TSW1400EVM

Hi,

We have some questions relating to use of the ADS52J90 ADC with the TSW1400 data capture board. We are intending to use these parts in an ongoing client-funded project.

We are hoping to confirm selection of the AD552J90 for the design and to place an order for multiple TSW1400 boards as soon as possible, but we first just need to confirm our understanding of their operation and capabilities.

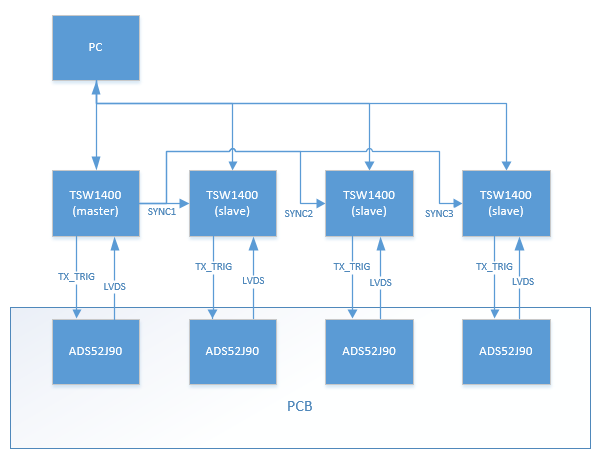

- We would like to capture data from four ADS52J90 ADCs. Each ADC will be connected to a separate TSW1400 data capture board

- The four ADCs will be mounted on our own PCB (together with the associated analogue circuitry)

- We need to capture data from all four ADCs simultaneously

- Our proposed configuration is shown in the diagram below:

Our questions are as follows:

- From page 30 of the TSW1400 user manual SLWU079D, we can see that it appears to be possible to use up to five TSW1400 data capture boards to capture data in parallel using one board as the ‘master’ and connecting each of the SYNC1, SYNC2, SYNC3 and SYNC4 outputs from the master board to the EXT_TRG_INPUT of a ‘slave’ board. Can you confirm that it would be possible to capture 1000 samples from four ADS52J90 ADCs (i.e. one master and three slaves) at the same time using this setup?

- Does each TSW1400 board also provide the TX_TRIG input to the connected ADC, or must we provide a separate source to drive the ADC TX_TRIG signal inputs?

- Are we correct in thinking that the ADC samples the input continuously, and the TSW1400 only captures the data when triggered?

- On the ADS52J90 eval board, there appear to be 3 different possible sources of the TX_TRIG signal into the ADC – either from an external source through an SMA connector, from the USB-UART converter or from the FPGA on the TSW1400 data capture board. For our application, should we take the TX_TRIG signal from the TSW1400 data capture board, or somewhere else?

- Is it possible to use the MATLAB automation described in SLAA752 to automate the capture of data from the four TSW1400s, so that all four capture data that was sampled at the same time, as we require?

- If it is possible to use MATLAB as above, how will that work? For example, will one board be the master and trigger the other boards to capture the data? Can the PC then connect with each TSW1400 in turn to download its data, and then return to the master board to trigger the next data capture?

- The setup above assumes that we will use a PC to initiate the data capture. Is it possible to instead send an externally generated hardware trigger signal to the four TSW1400 boards to capture the data and then transfer the data from each one to the PC some time after?

If anything is unclear, or you need any further information, please let me know.