Other Parts Discussed in Thread: LM2841,

Dear Sir :

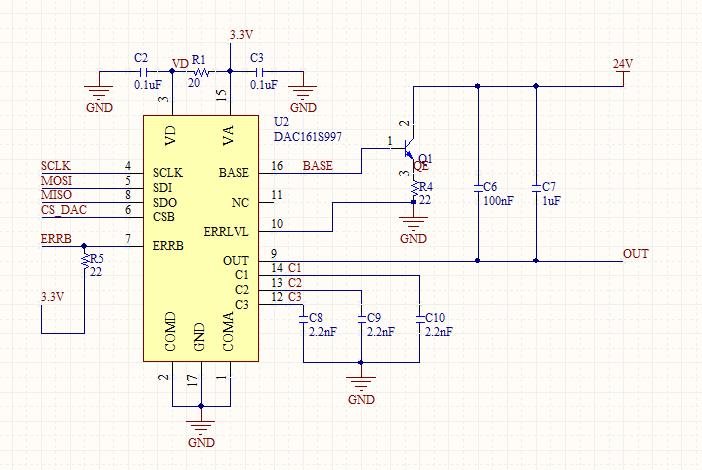

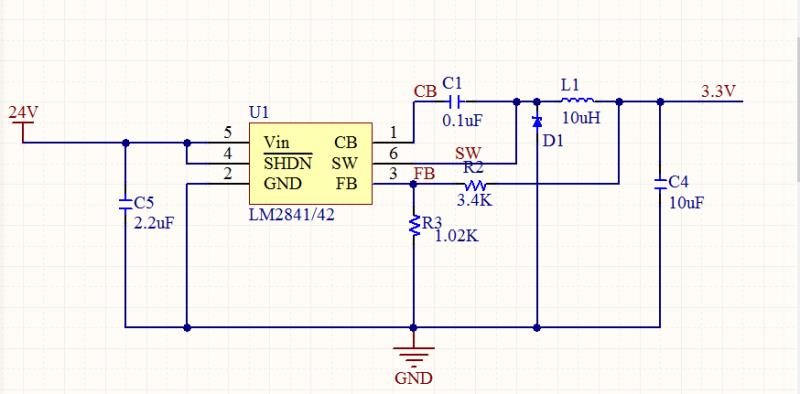

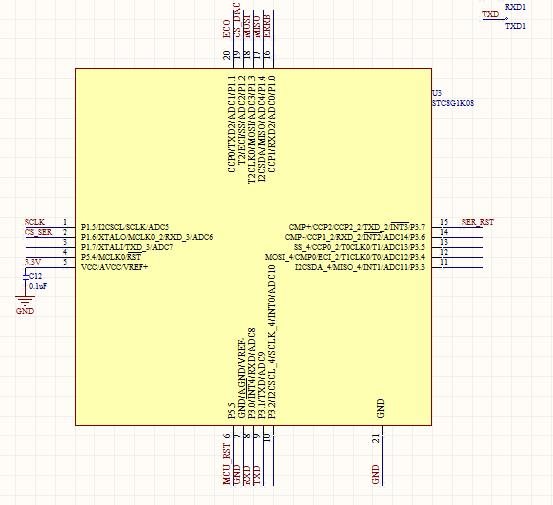

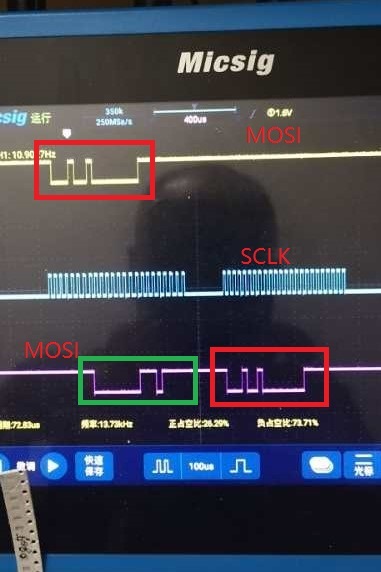

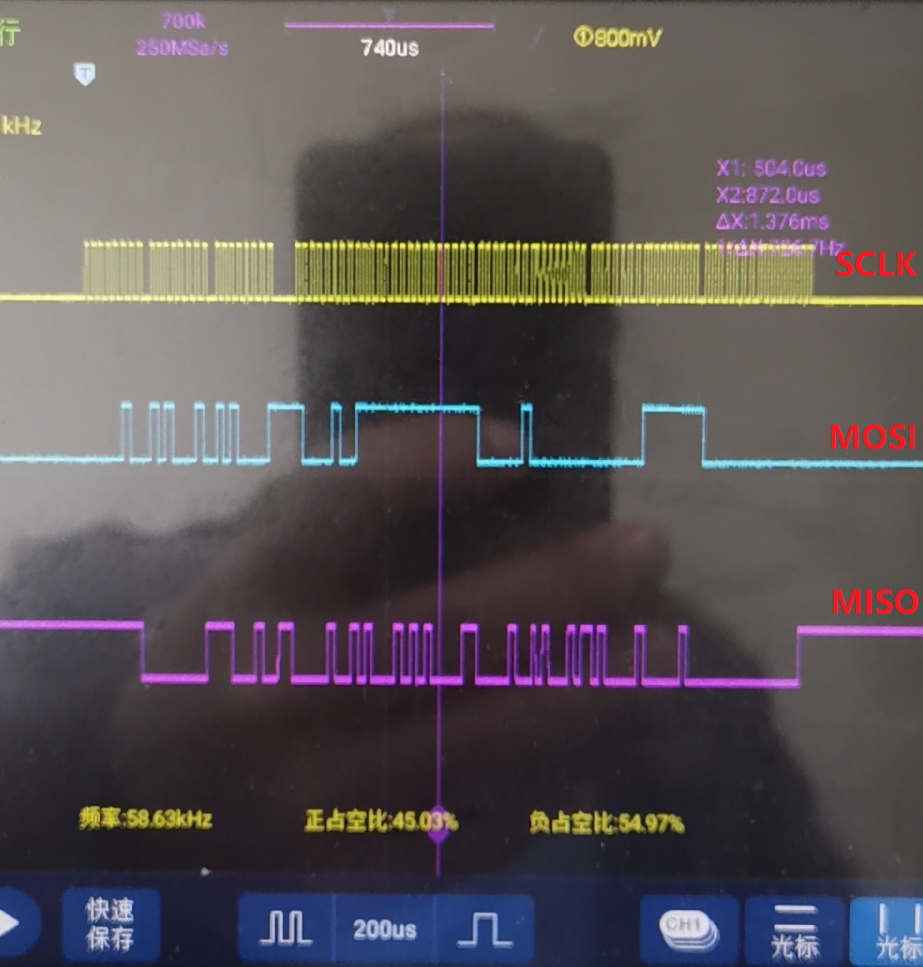

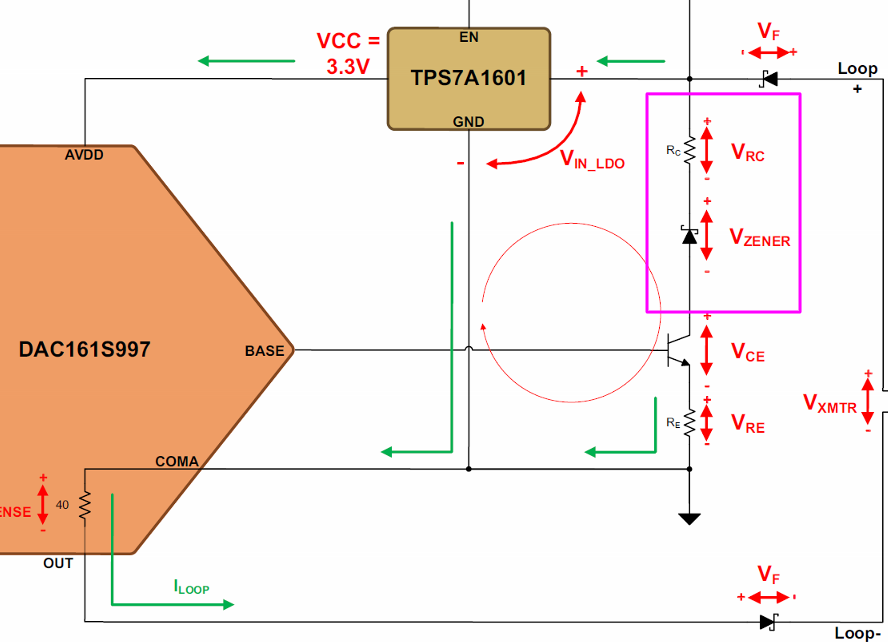

I plan use DAC161S997 , transfer SPI data to 4-20mA output , i almost use typical application circle . just change LDO to switch power LM2841. now i can communicated with MCU with Uart, but i can't get the right answer from DAC, when i send command to DAC . i use simulate SPI function . the code as below , pls. help me review it , very appreciate if you can give me some suggestion.

when i run test () , only get "FF" ,"FF","FF" from DAC .

/* read 1 bit from SPI. return data */

u8 SpiReadByte(void)

{

u8 i,rByte=0;

SCLK=0;

for(i=0;i<8;i++)

{

SCLK=1;

rByte<<=1;

rByte|=MISO;

SCLK=0;

}

return rByte;

}

/*SPI send 1 bit */

void SpiSendByte(u8 dt)

{

u8 i;

for(i=0;i<8;i++)

{

SCLK=0;

if((dt<<i)&0x80)

MOSI=1;

else

{

MOSI=0;

}

SCLK=1;

}

SCLK=0;

}

Void test ()

{

u8 outData[3], i;

CS_DAC = 0;

outData[0] = 0x04;

outData[1] = Data >> 8;

outData[2] = Data & 0xff;

for (i=0; i<3; i++)

{

SpiSendByte (outData[i]);

Delay_ms(20);

}

Delay_ms(2);

SpiSendByte(0x89);

w[0]=SpiReadByte();

SpiSendByte(0xff);

w[1]=SpiReadByte();

SpiSendByte(0xff);

w[2]=SpiReadByte();

CS_DAC = 1

}