Hi, I'm building a load cell, I'm having some trouble trying to understand how to fix this issue:

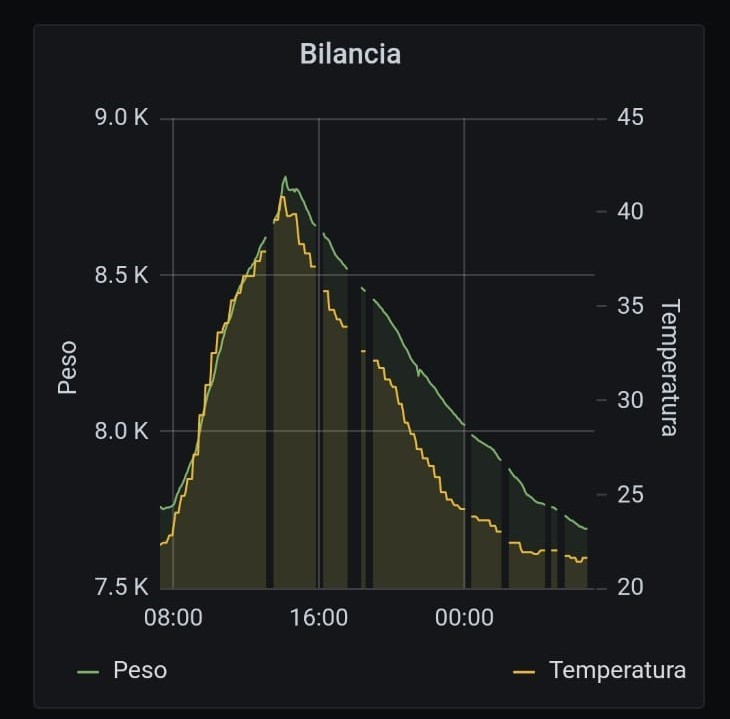

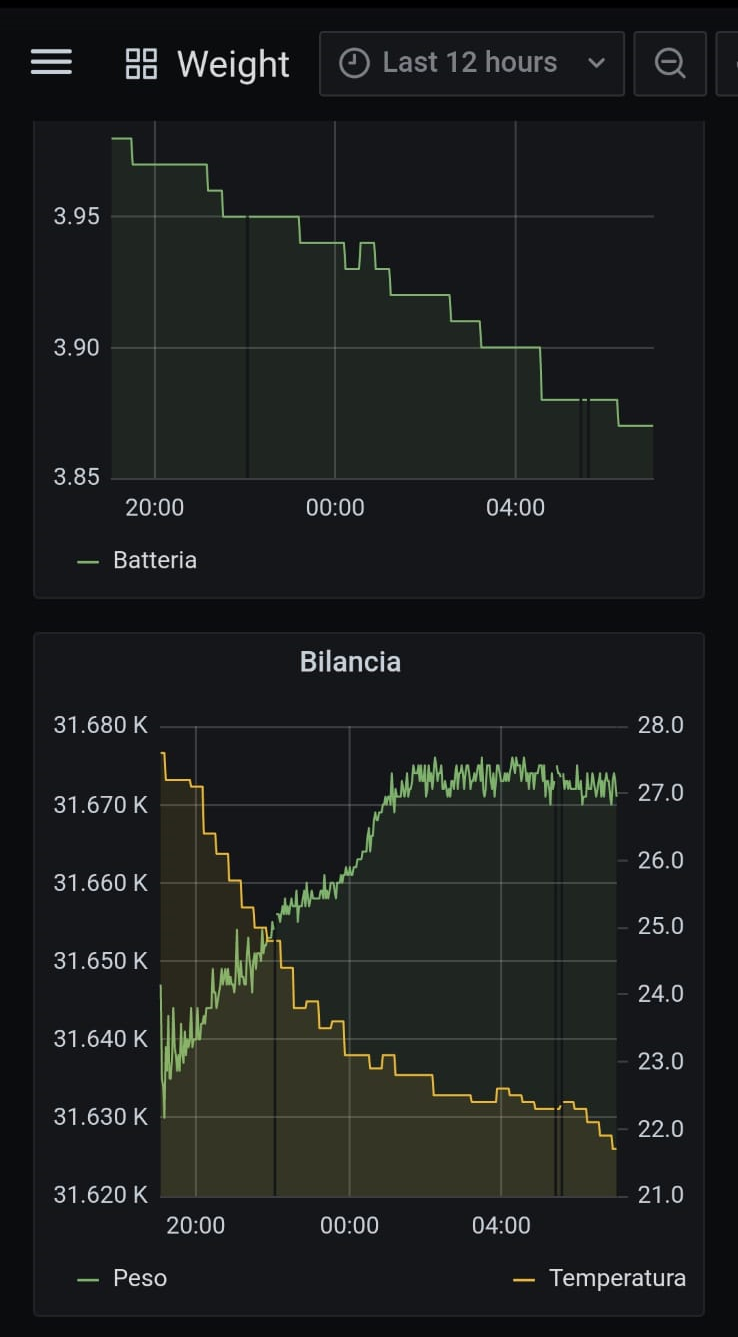

The load cell has a fixed weight on it, this is a 24h period outside, the reading of the temperature is made by a temperature probe fixed near the load cell, the code I'm using is here:

Can you please help solving this problem?

thanks

Simone