Other Parts Discussed in Thread: DAC8771EVM,

Hi Team,

I have designed my own application board using DAC8775. Configuration and voltage levels look ok, but I am not able to read status register and see outputs on the terminals.

I am using STM32 microcontroller to communicate with DAC8775.

Below is the configuration have done in STM32 for SPI:

1. Frame format: Motorola 2. Data size: 8 bits 3. First bit: MSB first 4. Prescaler: 32

5. Clock polarity: High 6. Clock phase: 1 edge 7. CRC calculation: Disabled 8. NSS signal type: Software

Voltages: DVDD = 5V, REFIN = 5V, VPOS_IN_A and VPOS_IN_B = 3.4V, AVDD = 12V

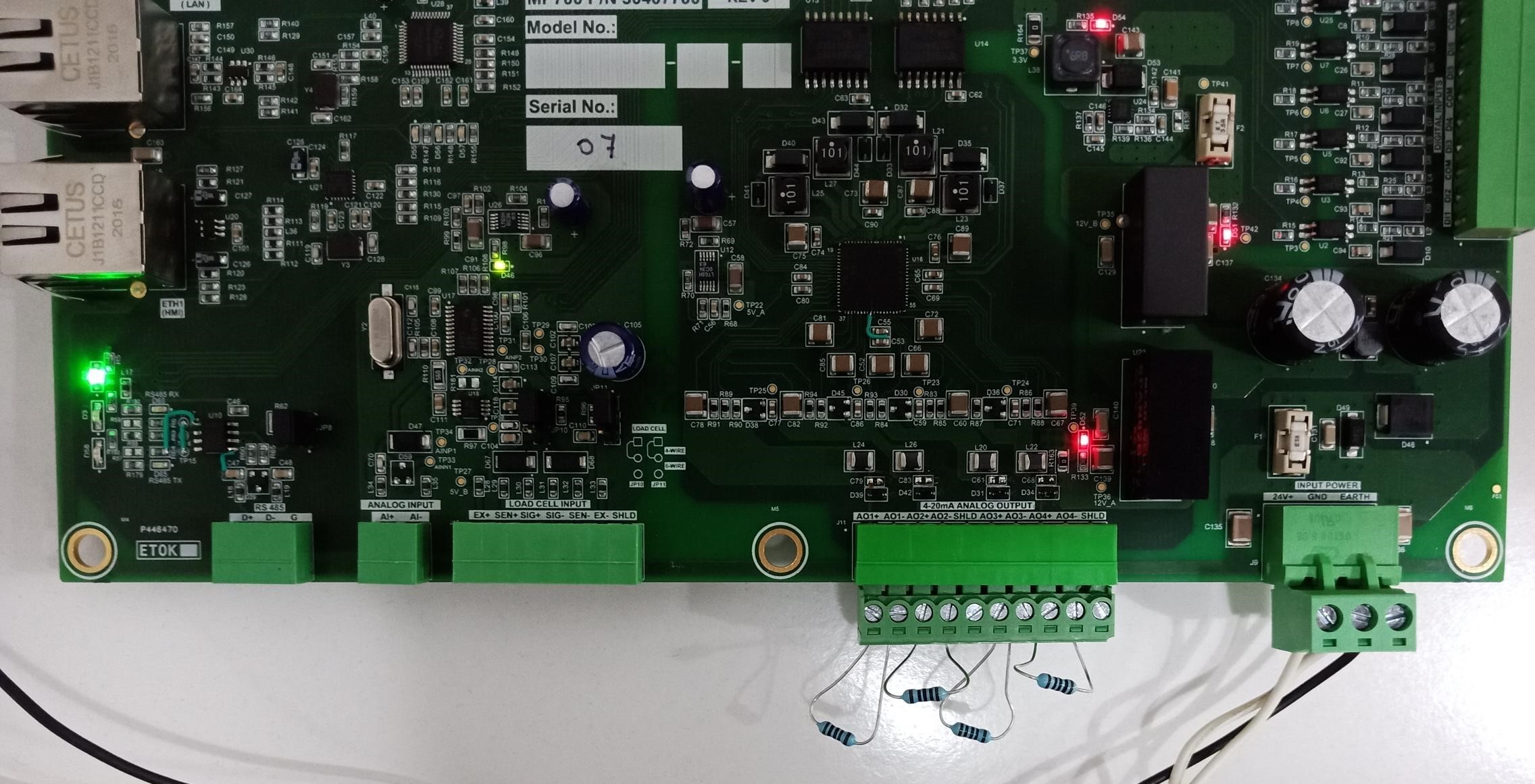

Please find below schematic.

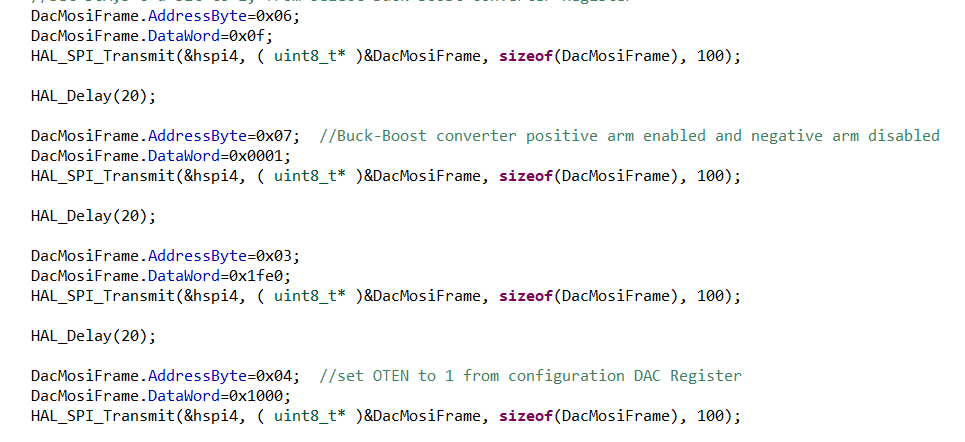

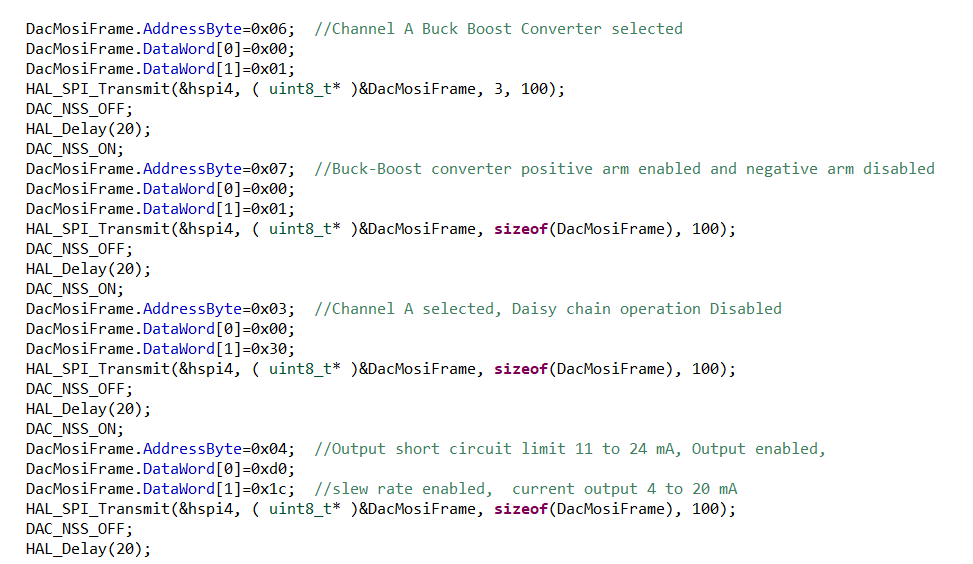

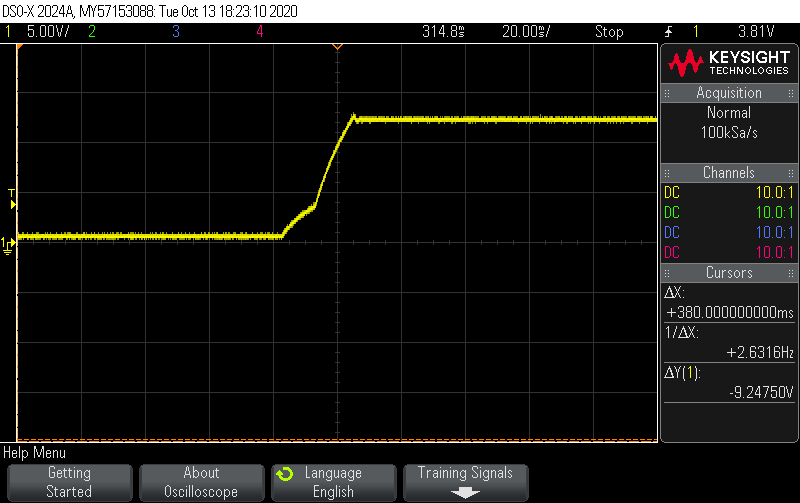

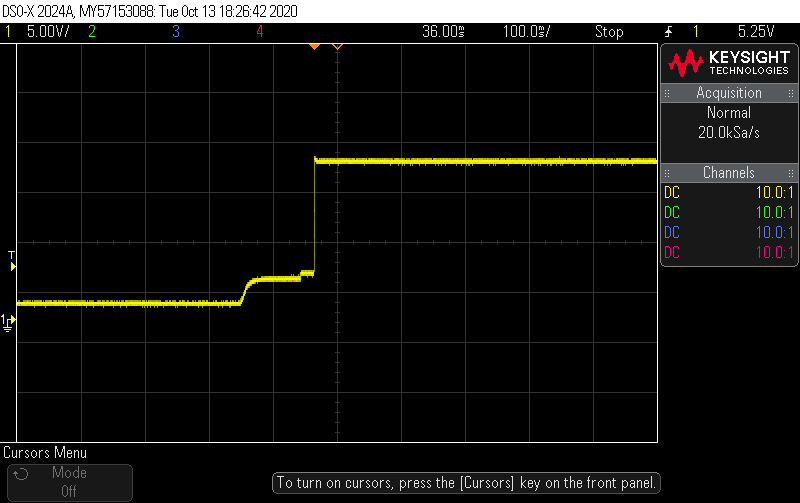

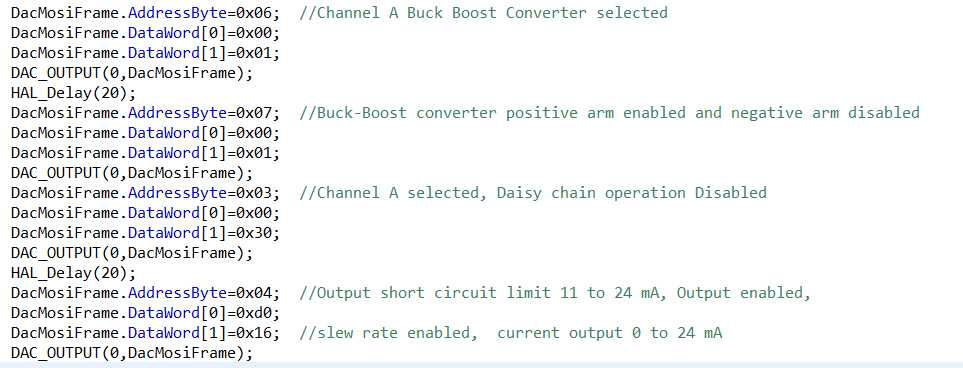

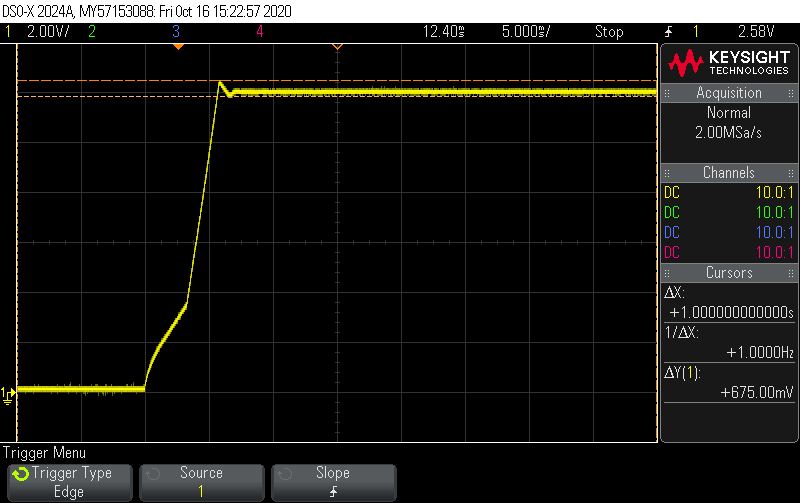

Also, please find below snapshot of configuration and waveforms:

Kindly guide me on this regard.

Than you.

Kiran