Hi,

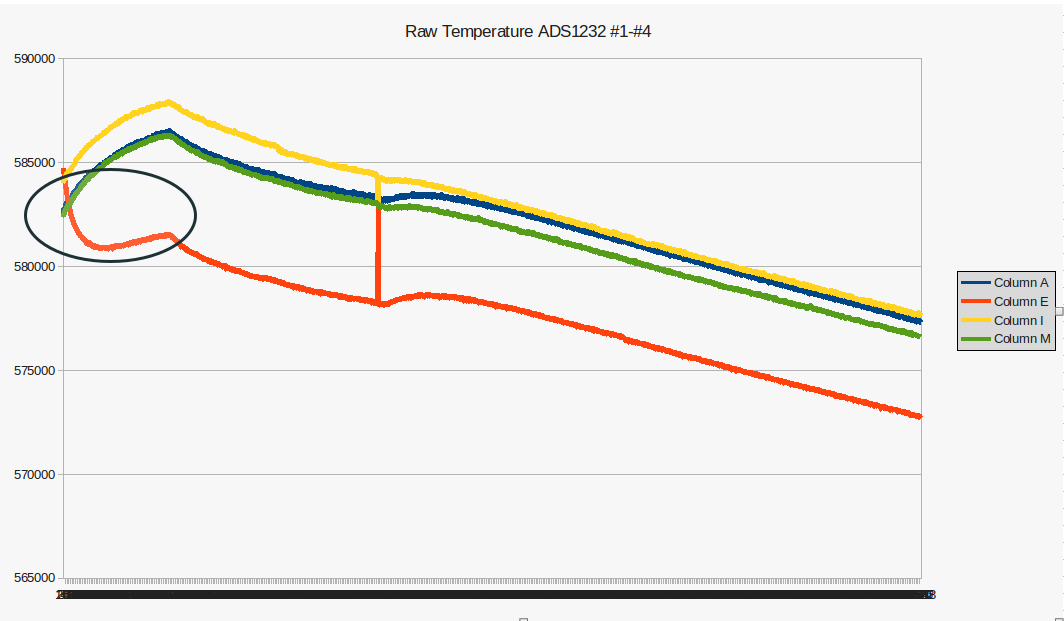

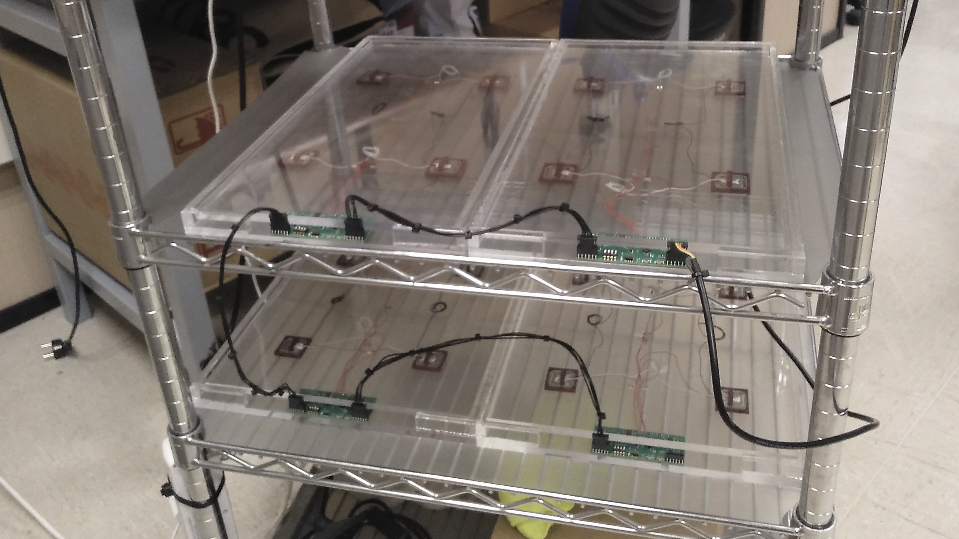

I'm testing four ADS1232 weight scales simultaneously and I have some doubts about the results obtained after a 15 hours of registered data (sample-time: 1 second). Here's the graph for the raw temperature of the four scales (#1:blue, #2:red, #3:yellow, #4:green)

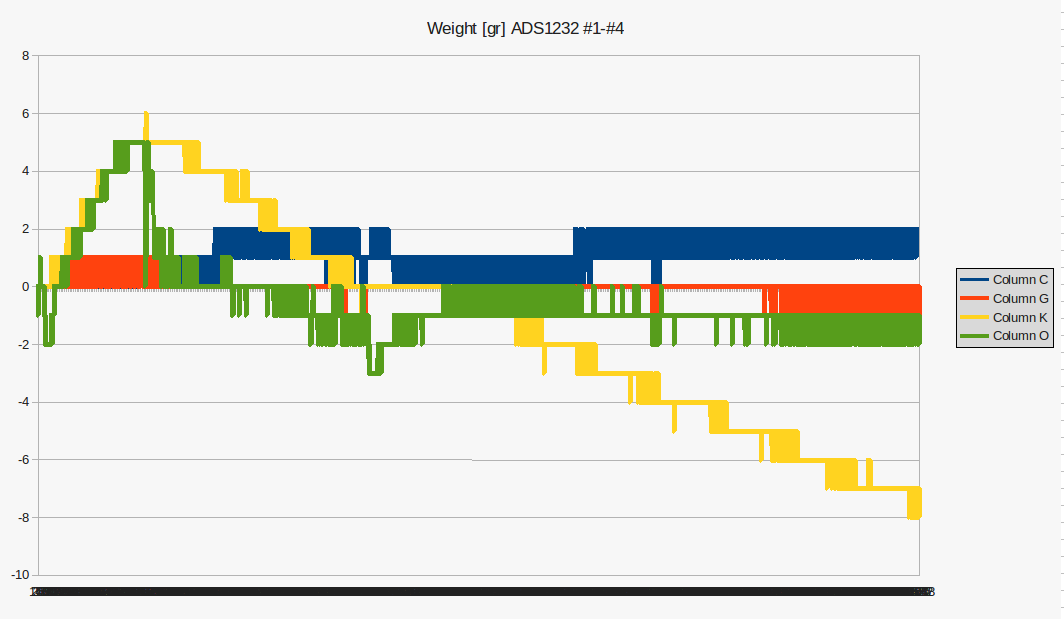

And here's the graph of the weight in grams (zero adjusted and scaled)

The peak that can be observed in the first graph does not worry me since it is probably due to some interference. However other behaviors are strange to me:

- Temperature versus time on scales # 1, # 3, and # 4 seem to follow the same trend, but scale # 2 has an inverse effect on the first recordings. What could be the cause?

- The variation of the weight recorded in scales # 1 and # 2 seems adequate to me, but the measurement in scale # 3 rises to 5gr and then falls to -8gr. It seems excessive to me.

- On the other hand, scale # 4 seems to follow the same initial slope as scale # 3 but from 5g it drops steeply to follow the same trend as scales # 1 and # 2.

thanks in advance,

gaston