Hi all.

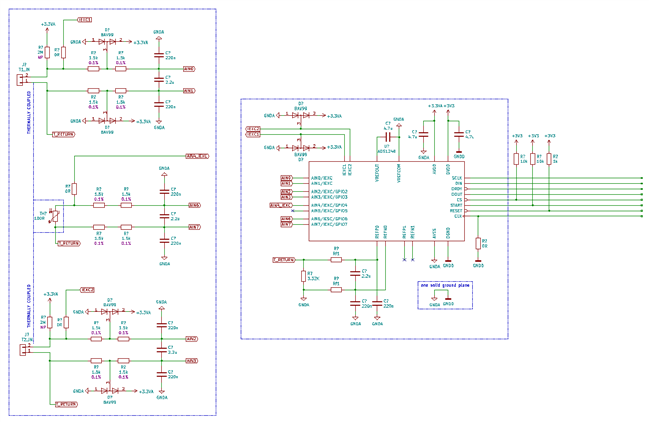

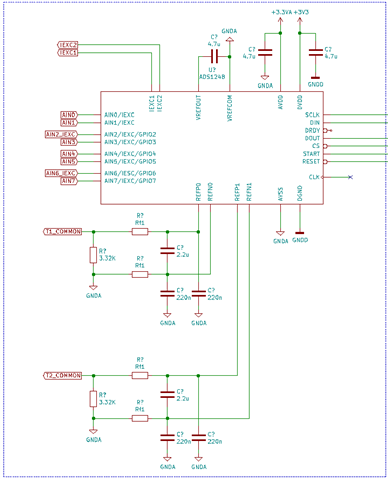

I'm developing a temperature sensor conditioning circuit (range 0°C to 350°C) for a custom industrial device. This device will acquire the temperature of two objects, and I need to allow free choice between RTDs or thermocouples as sensors. Specs are:

- two temperature inputs;

- RTD, PT100 type, two wire connection;

- J or K thermocouples with cold junction compensation;

- two inputs have the same sensors: two RTDs *or* two TC. No sensor type mixing allowed.

- 4 readings per second for every input;

I'd like to avoid the use of external analog muxes, so I've come up with this solution ('NP' in schematics means 'Not Present'):

Questions are:

- Is there anything wrong/could it work?

- in case of TC sensor:

- IEXCx can be activated to detect a burnout/disconnected sensor (instead of IBOR source and sink)? This should bypass the filtering resistor imbalances.

- Should I disconnect IEXCx mux *before* acquiring a new measure, or can I simply keep it on all the time?

- REFPx/REFNx are here because they are needed for RTD operation. So they are not intended to perform a ratiometric measure. As per my understandings, REFPx will bias the TC junction common mode voltage to proper PGA/ADC operation (IEXC should be active?), and the 3.32K resistor between REFPx and REFNx becomes a dummy load for the voltage reference generator. Am I correct? Could this work properly?

- I'll use two spare adc inputs (for each sensor input) for two wire PTC measure (smd 0805 PT100 sensor, close and thermally coupled to the input block terminal), with ratiometric measure through REFPx/REFNx inputs. I should disconnect IEXCx from TC input, activate IEXC through internal mux, set the correct PGA gain and start a conversion. Is this ok?

- In case of RTD sensors:

- is there any real point using REFP1/REFN1 and REFP2/REFN2 inputs, one for each RTD sensor? I feel that using them both gratifies my sense of symmetry, but it will cost more pcb room for RC filtering. What purpose REFP2/REFN2 inputs are intended for?

- Is there any reference design for dual sensor type (RTD or TC) input conditioning, without using external analog muxes?

This circuit section will be replicated many times in the same board with an fpga as a conductor, so I'm really trying to get it right first time!

Thank you in advance!

Cheers,

Eugenio.