Other Parts Discussed in Thread: FDC2214

Hi Friends,

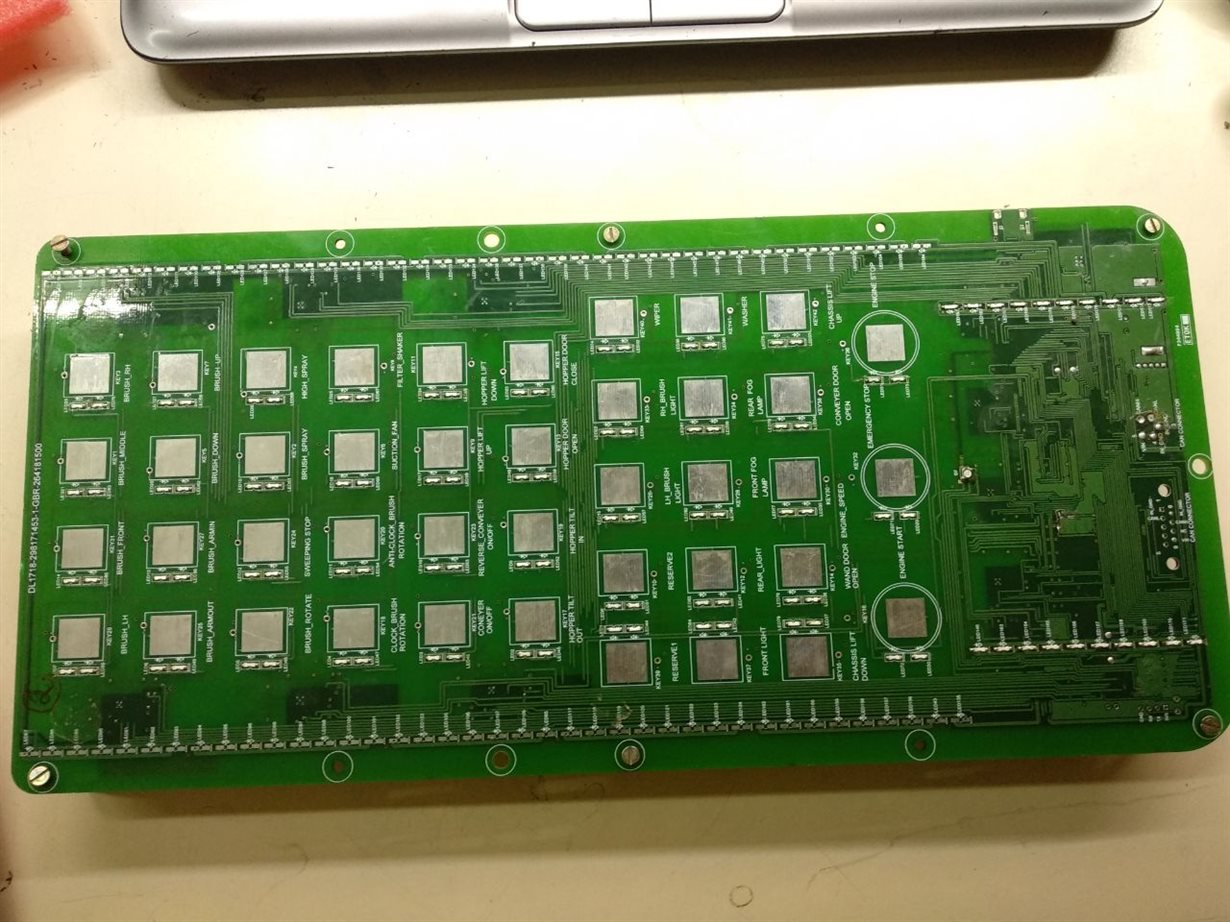

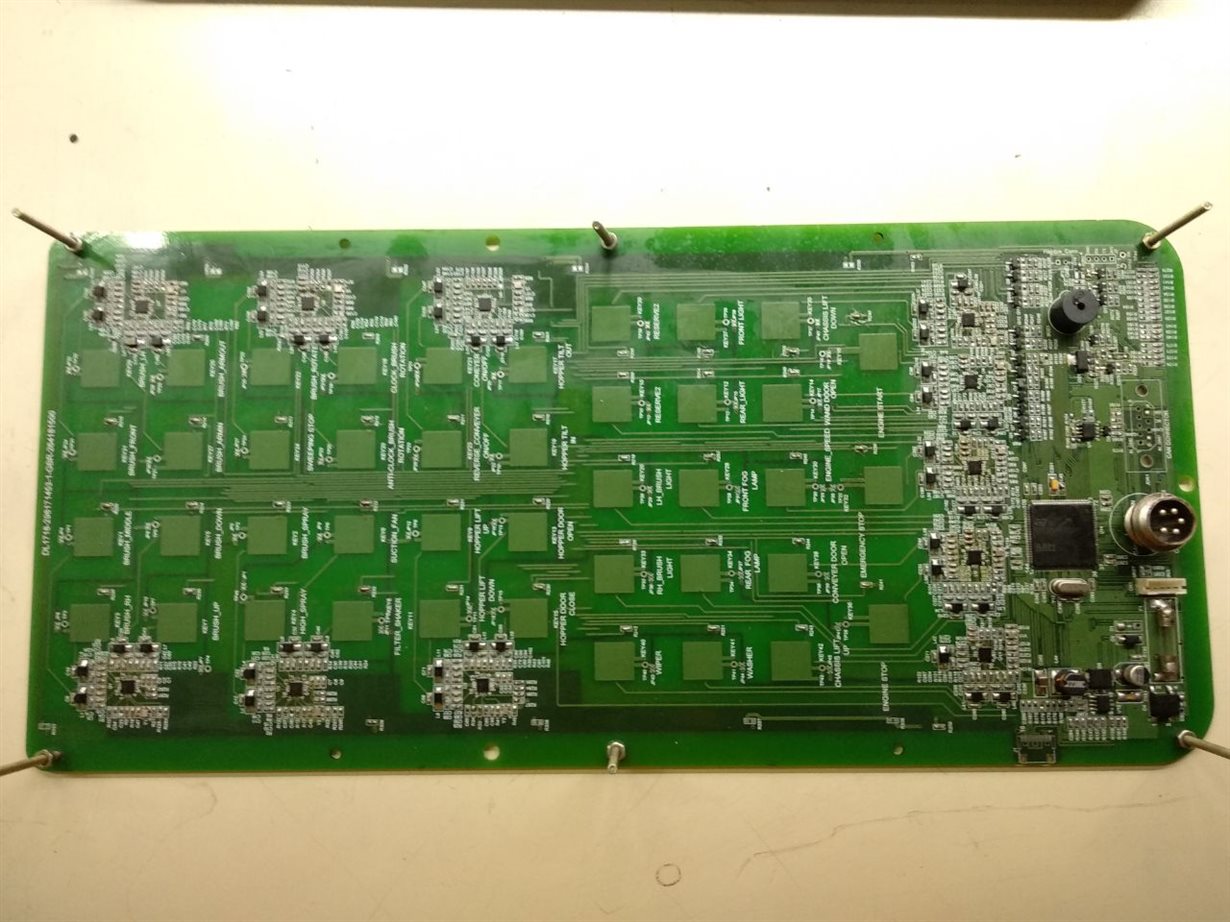

We are working on 44 Keys automotive cluster keypad based on FDC2214 and used 11 Nos of FDC2214 in this design with STM32L4R.

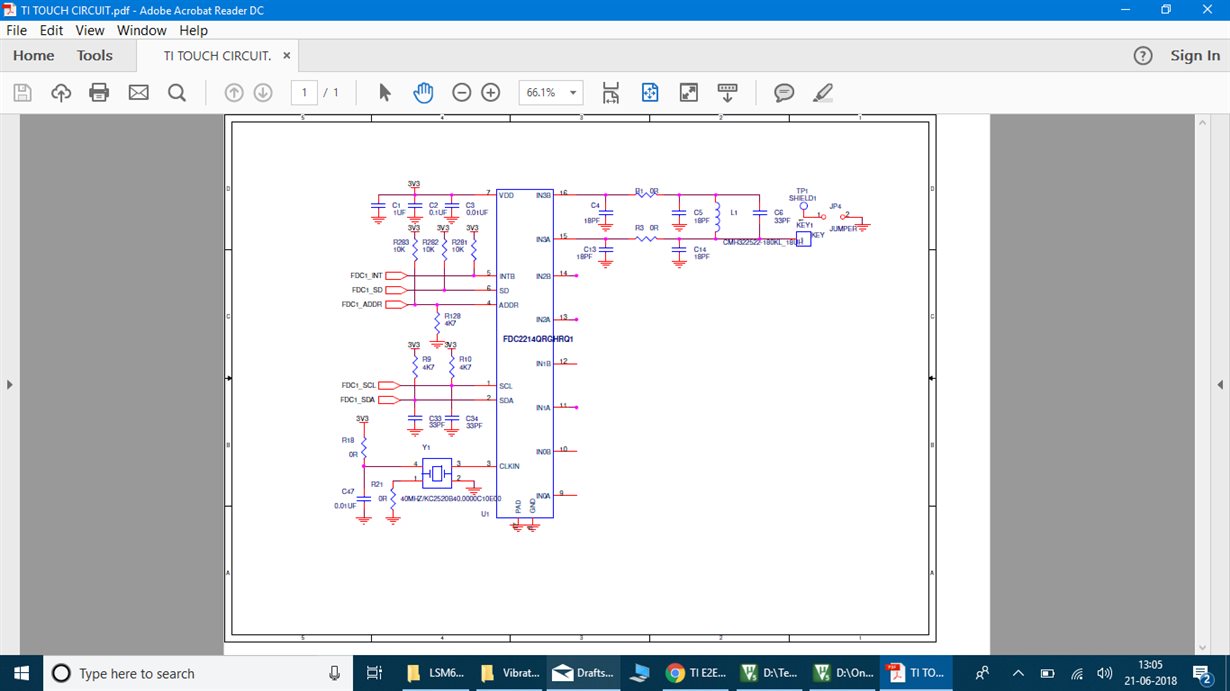

The four layer PCB picture is attached herewith (top and Bottom) and the used circuit is also attached which was derived from the Eval board of FDC2214.

The same software of STM32L4 is working fine with FDC2214 Eval board but not with custom board made whose picture is attached where the same micro is used with same software.

I think we are doing something wrong in the hardware as the same software on same micro is working fine and even we are able to read device address which shows that device is responding on the 44 keys keypad.

Kindly suggest how should we check FDC2214 and what all reason could be there for non generation of INTB.

Thanks in advance!

Thanks and Best Regards,

VK Verma