Other Parts Discussed in Thread: DLP9000, DLP670S, , DLPC900

we are looking to move to the latest version of our exist DMD. as such we have the hardware below.

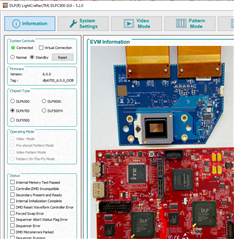

when we run LightCrafter it says the board is DLP670S not DLP9000 see below. and the board seems 'connected' but is unresponsive - can not enable video mode and no status reported.

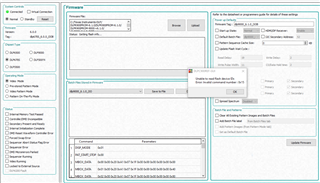

when we try to upload new firmware (master and slave), after saying YES to up dating the boot loader, we get the following error...

we are stuck and need this new DMD to work as a replacement for our old 9000 series 2560x1600 DMD is no long available!

any help greatly appreciated!