Other Parts Discussed in Thread: LM25141, LM3409, TPS99000

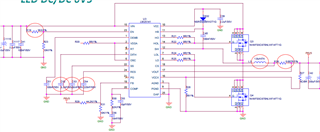

Hello, now we are going to design the driver board of DLP5530, which is used in automotive electronic products. The working voltage is DC 9V-16V. I see that there is a pre-regulator circuit of LM25141 in the LED driver part, which reduces the input power to 6.5V or 8V, and then inputs to the LM3409 chip. Is this LM25141 pre-regulator circuit necessary? We design whether the input power supply can be directly connected to the LM3409 without using the pre-regulator circuit.thanks