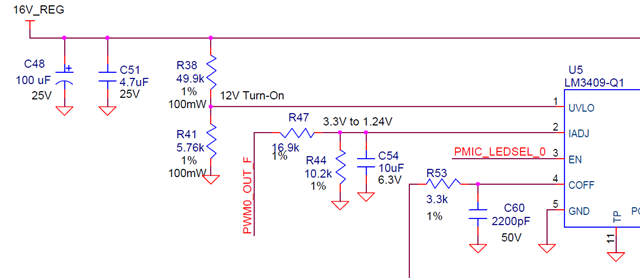

Other Parts Discussed in Thread: LM3409

Tool/software:

Hi teams,

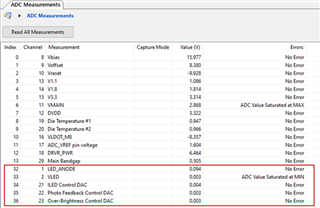

I would like to ask meaning of ADC measurements at DLP230 Control program.

We're trying to modify DLP4621Q1EVM to drive laser diode, so that I would like to check ADC measurements which can be monitored at DLP230 Control program.

Could you let us meaning of ADC measurements related to LED and which IC measures them?

|

ADC Measurements |

IC |

Pin |

Description |

|

LED_ANODE |

TPS99000 |

ANC_IN1 ? |

|

|

VLED |

|||

|

ILED Control DAC |

TPS99000 |

IADJ ? |

|

|

Photo Feedback Control DAC |

TPS99000 |

TIA_PD1 |

|

|

Over-Brightness Control DAC |