Tool/software:

Hello TI team,

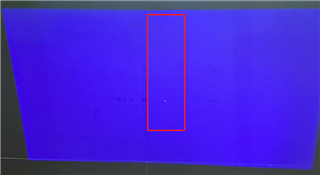

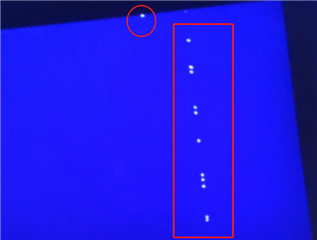

We have mentioned this problem last time, but recently we have similar problems, that is, there are bright spots or vertical lines on the DMD screen.

Our workshop has already done ESD protection, including tables, materials and personnel.

In addition, we will not discuss the structure of Optical Engine, FPC, circuit board, assembly process, testing methods and other influences for the time being, because we have spent time to verify the above possible problems, but found no obvious anomalies; And in different product models, different material specifications, different material batches and different manufacturing processes, DMD may be damaged. However, in previous production, DMD damage was rarely found, so the above effects will not be discussed first.

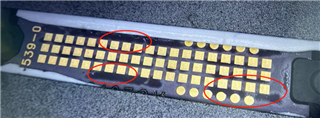

In recent production, it was found that DMD was damaged, and the defective rate was about 10%, which was too high. It is shown as a single bad point, multiple bad points and bad vertical lines of DMD. A single bad spot may damage a single pixel or multiple pixels, because some are brighter and some are darker.

The following figure:

Most of the processes with defects are inspected at the end of aging. The aging process is to switch to the dark field observation picture with low LED current. After no defects are found, switch to the internal chessboard test picture and continue to work for more than 8 hours. After the end of the time, switch to the dark field observation picture without interruption, and observe whether there is any defect in the picture.

And we found that there are some other problems, for example, there is a DMD, sometimes there will be bright spots when looking at it, and sometimes it is found that there is no bright spot. There are also some DMDs, which can see the bright spot when they just switch to the dark field, but after a while, the bright spot will disappear instantly. This is strange and we can't understand it.

The batch information of the above two DMDs is as follows:

Based on the information provided above, I want to know if there are any other possible reasons for the damage of DMD, and provide some suggestions for improvement.

Thank you.