Other Parts Discussed in Thread: DLP4500

Tool/software:

Hi, I am evaluating the DLP4500NIR DMD for a broadband spectral system and need a clearer picture of the optical losses inside the hermetic package.

From the datasheet I see that:

-

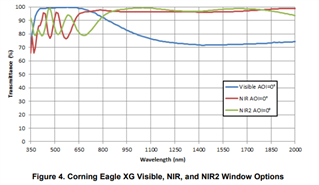

The window assembly is specified for high transmittance from ≈ 700 nm to 2000 nm.

-

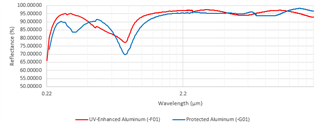

The micromirror array is aluminium-coated, so I expect relatively high reflectance well beyond the NIR and for visible wavelengths.

However, my application spans a wider band—400 nm to 2000 nm—including the visible range. Could you please share (or point me to) the following information?

-

Window Assembly / Package Window

-

Typical or minimum spectral transmittance curve from 400 nm to 2000 nm at normal incidence.

-

Any change in performance at oblique angles (e.g., 24° ± 1°, the nominal micromirror tilt angle).

-

-

Micromirror (Aluminium) Array

-

Typical spectral reflectance of the mirror surface over the same 400 nm – 2000 nm range, preferably at both normal incidence and the ±12° operational tilt angles.

-

Confirmation that the mirror coating/process is identical to the one used in the visible-optimized DLP4500, or note any differences specific to the NIR device.

-

-

Overall System Throughput

-

If available, a combined throughput or efficiency curve (window × mirror) would be very useful for preliminary SNR calculations.

-

Even approximate curves or representative data would be extremely helpful! Or recommendation for any other DMD devices that has broad wavelength range from 400nm to 1500nm would be also helpful!

Thank you,

Suhyun.