Other Parts Discussed in Thread: DLP9500

Tool/software:

The DLP 9500 product(Vialux V-9501 UV) is suitable for the laser band from 363 to 420nm, but I use the 355nm and 405nm wavelength lasers at a 24° angle, the brightest reflected spot appears in the center, it works fine, but with the same angle of 380nm laser, its reflection angle changes a lot, and the main order spot disappears, I want to know what causes this phenomenon and how we can avoid this problem.

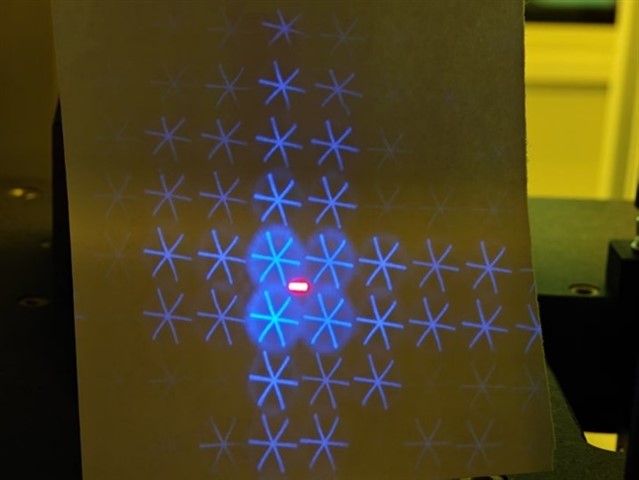

380nm laser irradiation

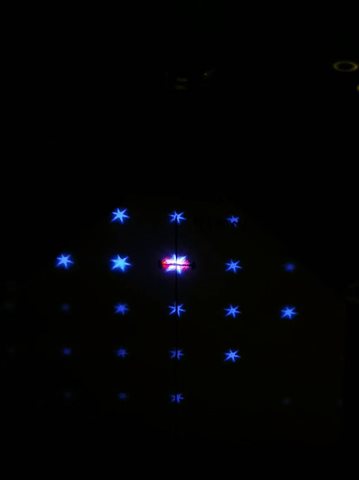

355nm laser irradiation