Hello DLP ALC team,

I have got a question from our customer. It seems they are seeing the problem in LightCrafter4500.

Please see below and would you please give any advices to solve the problem?

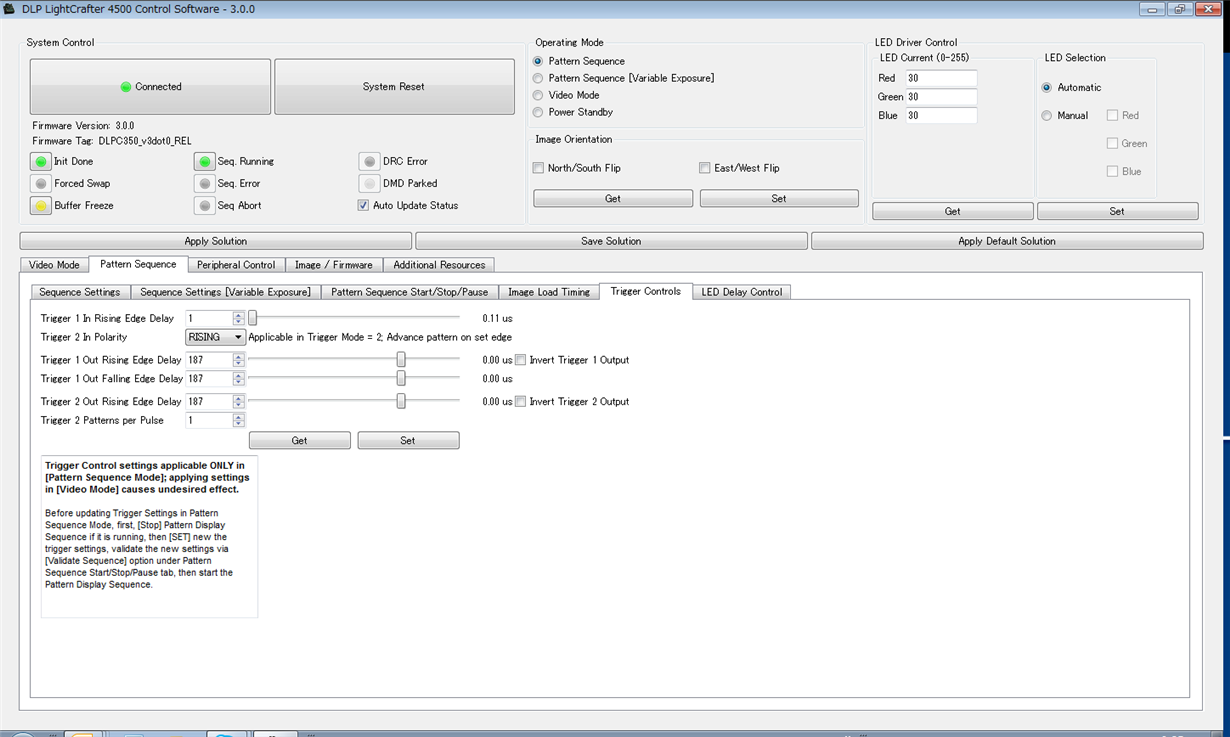

[LightCrafter4500 Configuration]

- Pattern Sequence Mode

- Color : White

- Trig : External Positive

- Flash : index0, 1 8bit

- Pattern 8bit × 6

- Pattern Exposure: 8333us

- Pattern period : 8333us

- Trigger Frequency : 14Hz ~

[Problem]

Phenomenon 1

If they turn on and off the external trigger signal repeatedly, the brightness of the image becomes sometimes normal and sometimes dark.

A reproducibility is higher.

When the image is darker, it looks the waveform of LED current is inverted as compared to the normal working.

Phenomenon 2

Despite they set the external trigger mode, the internal trigger works and LED turns on (the image is displayed).

In that case, if they try to turn on and off the external trigger, the brightness of the image becomes sometimes normal and sometimes dark

[Question]

They are thinking that this may be the problem of the DLPC350 firmware.

Would you please give any advice to solve this issue or provide any workaround to avoid this problem?

Best Regards,

Nobu Arai