Hi,

I have question about Mounting condition of DLP6500.

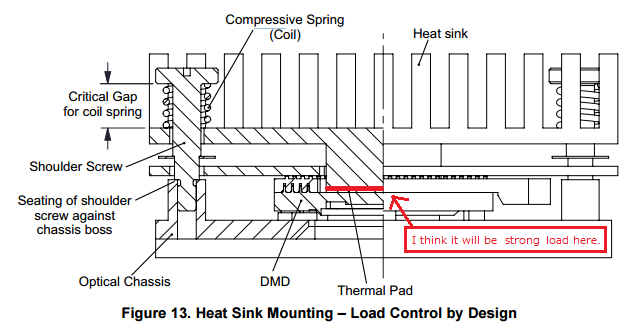

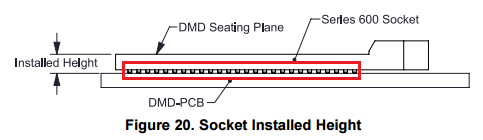

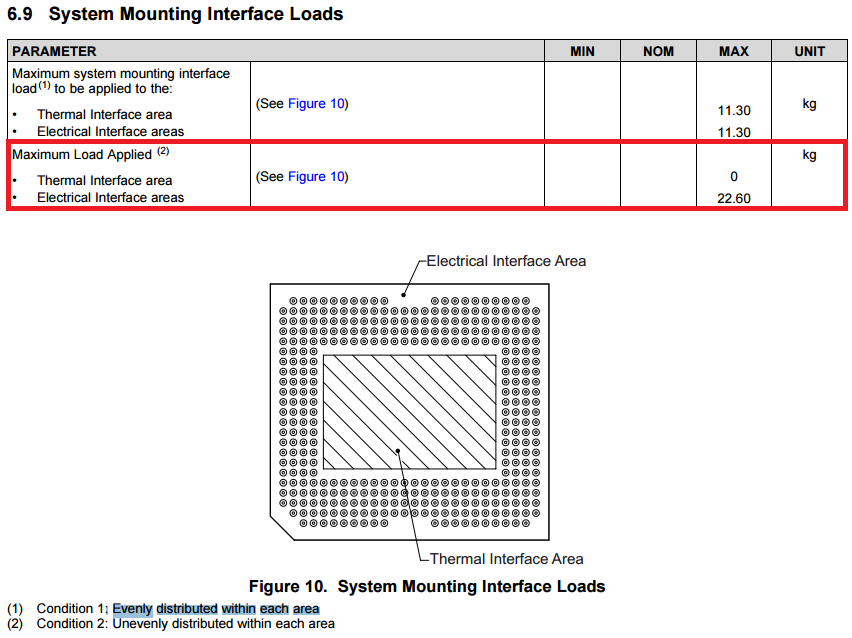

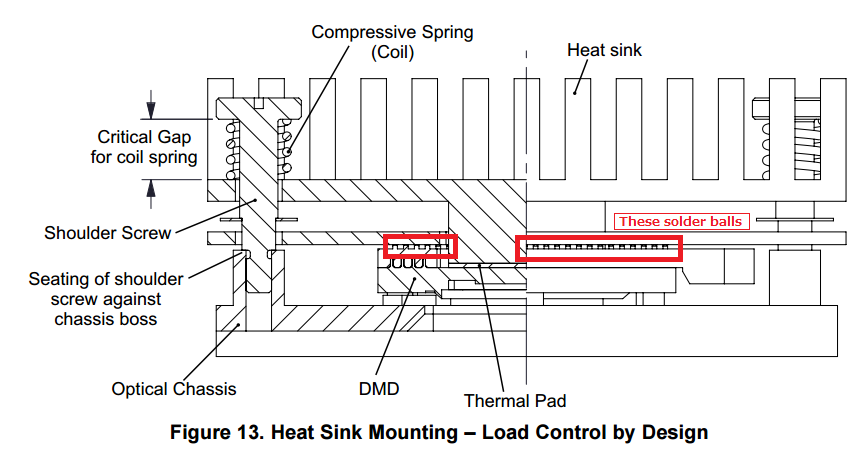

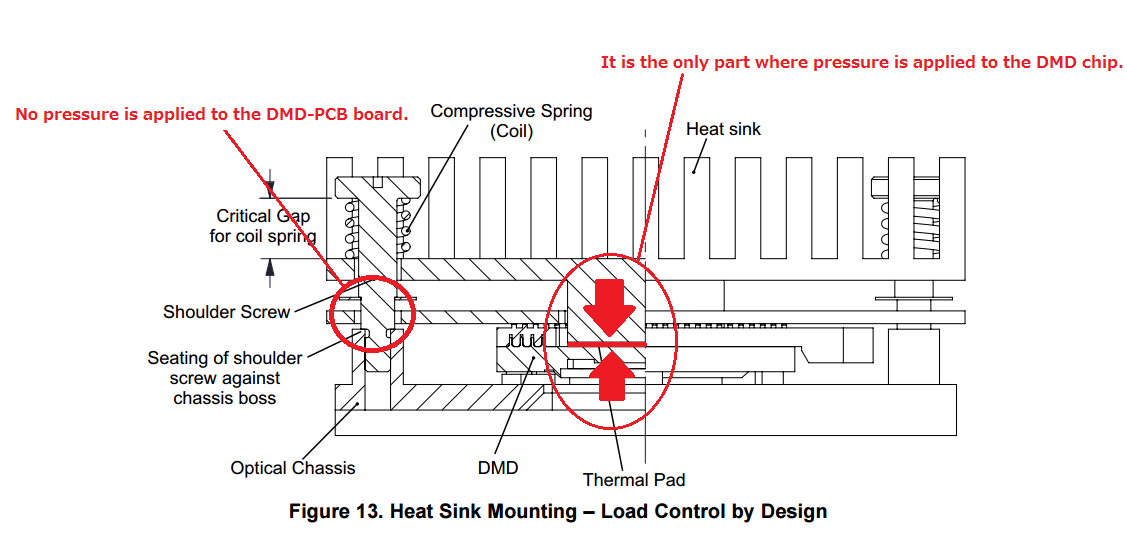

The following documents describe the load of Thermal Interface Area and Electrical Interface Area, Is it possible to install the DMD by equally loading only the Thermal Interface Area?

In other words, is it possible to fix the DMD only with Thermal Interface Area excluded Electrical Interface Area?

Best regards,

H.U