Other Parts Discussed in Thread: DLPC900

We are using a 3DLP9000 UV Light Engine controlled by the Lightcrafter 9000 EVM which uses 2 DLPC900's in a master-slave configuration. Recently we noticed that the projection area corresponding to the master DLPC900 illuminates with a faint background artifact image. We do not recognize the image displayed. This faint background image displayed changes slightly depending on what is being projected, but largely stays the same. Resetting to default DLI or TI firmware does not solve the issue. One example image, when we project an example provided image file with a single dot (which displays correctly as you can see):

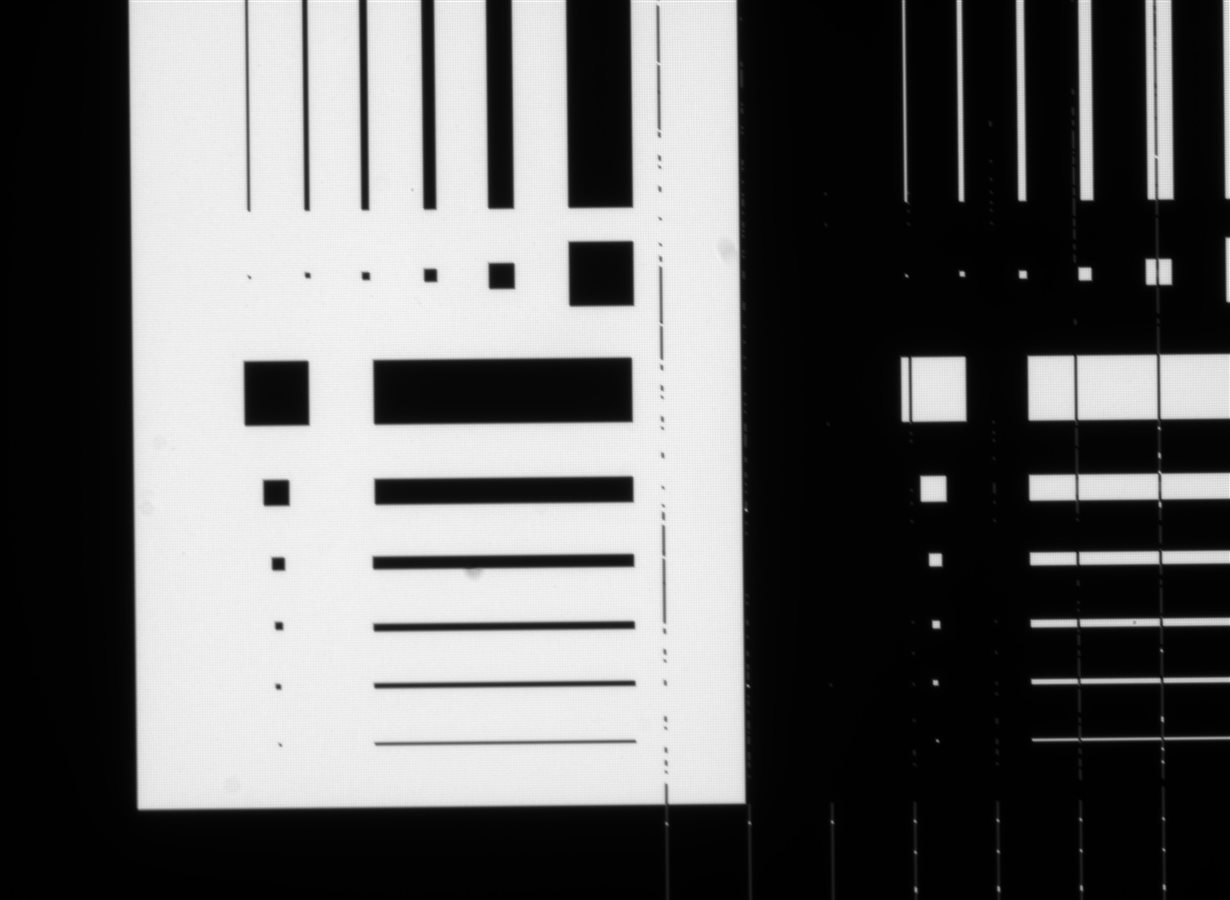

Another example image taken from a UV camera shows streaking lines crossing through the pattern.

The artifact was first observed after a pattern/image upload which caused an error. The upload was attempted from the GUI we are developing based on the API used by the DLP Lightcrafter DLPC900 GUI.

The Master DLPC900 red fault status LED was pulsing indicating an internal fault in the controller. The fault was identified as 4 critical error pulses, 1 module error pulse. The following is the UART debug log from connection to the error occurs:

Debug opened on URT0

Memory test cc = 1

API version: 05.00.01

App version: 05.00.01

Configuration layout versions:

Seq Map: 44.21.0100

SW Map: 44.21.0000

I2C Cmd Slave Address 34

Slave ASIC is Ready (0).

DRAM memory pool 004025E8 200025E8

ptn_seq.c (1014) >> Failed

Illumination: Transition to operating mode

Configuring LED Enable and PWM Driver...

PWM Driver initialized...

Setting PWM Drive Levels...

Controller Product ID: 06

DMD Type: 7a

DMD Product ID : 24

System Mode: There are 1 defined System Modes

System Mode: System Mode 0 supports 2D

Sysmon: Executing Default Batch file

Illumination: Transition to operating mode

Configuring LED Enable and PWM Driver...

PWM Driver initialized...

Setting PWM Drive Levels...

*** Data abort near 00001a54 ***

"Data abort near 00001a54" is where the error occurs, but "ptn_seq.c (1014) >> Failed" may be where the persisting artifact is coming from. "ptn_seq.c (1014) >> Failed" also shows up on the debug log when just using the provided DLP Lightcrafter DLPC900 GUI. Could this be from some corruption caused by the error we are encountering?

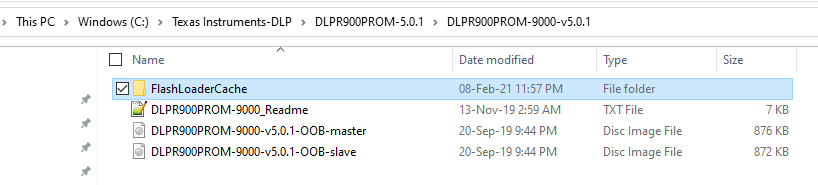

The following is a log of the commands sent to the DLPC900C through USB (3 images/patterns attempted to be sent):

1A1B : Set on the fly mode

1A34 : Define Pattern (x3)

1A31 : Pattern Config

1A2A : Init BMP Load (Master)

1A2B : BMP Load (Master

1A2C: Init BMP Load (Slave)

1A2D: BMP Load (Slave)

0101 : Read Error Code Description

0101: Read Error Code Description

After the error occurred, the system was reset, either through disconnecting the power brick from the outlet or hitting the reset button on the board. Upon rebooting the system, the error disappeared. The artifact was first observed during the next projection experiment after the error had occurred and has persisted since.

The light engine and board have been mounted for several weeks now and have not moved, so we do not think that the EVM flex cables have been damaged.