Hi expert,

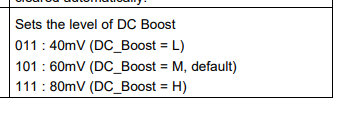

My customer is using TUSB213 in their project. Could you please help check the voltage accuracy of DC boost? Because customer want to use this spec to calculate the max voltage of USB and want to know the max divation value of it. But I don't find the spec in datasheet. Many thanks!

BR,

Jiaqi