Other Parts Discussed in Thread: DP83TD510E

Tool/software:

Dear Ti Team,

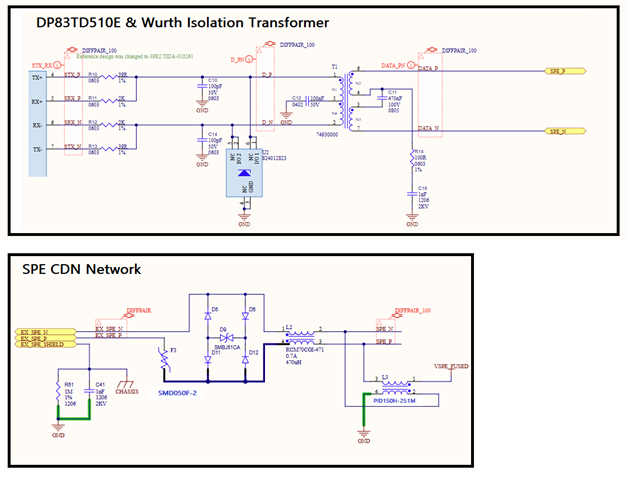

We are currently implementing an engineered PoDL solution without SCCP, most closely aligned with Class 14. For context, our design uses 48V DC at the PSE delivering 30W, and a minimum of 30V at the PD consuming 20W. Our current component selection for the SPE coupling and filtering network includes:

Ti SPE PHY: DP83TD510E

Wurth Isolation Transformer: 74930000

TDK PoDL Inductor: PID150H-251M

TDK Common Mode Choke: RCM70CGI-471

Our system is operational, successfully injecting PoDL and maintaining a stable SPE link over 250m of CAT6 UTP cable, with the PD powered via PoDL.

We’ve reviewed TI’s reference designs and PoDL application notes and have a few questions regarding recent updates:

Transformer Update – Wurth 74930200 vs 74930000:

We noticed the isolation transformer has been updated to PN: 74930200 in newer TI designs. This part does not appear on Wurth’s website, could you clarify if it is in pre-production? What was the reason for this change and is the 74930000 still considered suitable for PoDL applications?DC Blocking Capacitor Value Change:

The center tap DC blocking capacitor on the transformer has been revised from 470nF to 100nF in recent designs. In addition some notes show 2 × 100nF, while Wurth’s PoDL filter design app note suggests 2 × 470nF per line. Could you explain the the reason for this change?

Is this change only required if the new 74930200 is designed in or is this update required when the selected TDK DMI and CMC are used for PoDL, which essentially form an LC filter?

Is this capacitor change also recommended for non-PoDL SPE designs when not provisioning the DMI and CMC?

TX Resistor Value Change:

We observed that the DP83TD510E SPE Tx resistors have been updated from 49.9Ω to 39.2Ω. What prompted this adjustment? Is this update only required for PoDL designs or also a requirement for non-PoDL designs or is this to compensate for the change to the new 74930200 Transformer?Polyfuse Protection on Connector Interface:

In addition to the standard 4 steering diodes and TVS suppresion diode on the connector’s primary side, we are considering adding an SMD050F-2 polyfuse to protect against accidental high-voltage connections. Bench testing with a single series SMD050F-2 on the SPE_P line directly at the connector before the diodes and TVS show no obvious impact on link performance. Do you foresee any issues with this approach under different operating conditions or cable lengths?See our design reference images below for context:

We appreciate your insights and guidance on these points to help us align our design with best practices and performance.

Best regards,

Daniel Haddad