Other Parts Discussed in Thread: STRIKE

Hello,

the TRS213 has an integrated ESD protection that works well. But we have one scenario in the field that causes the IC to burn.

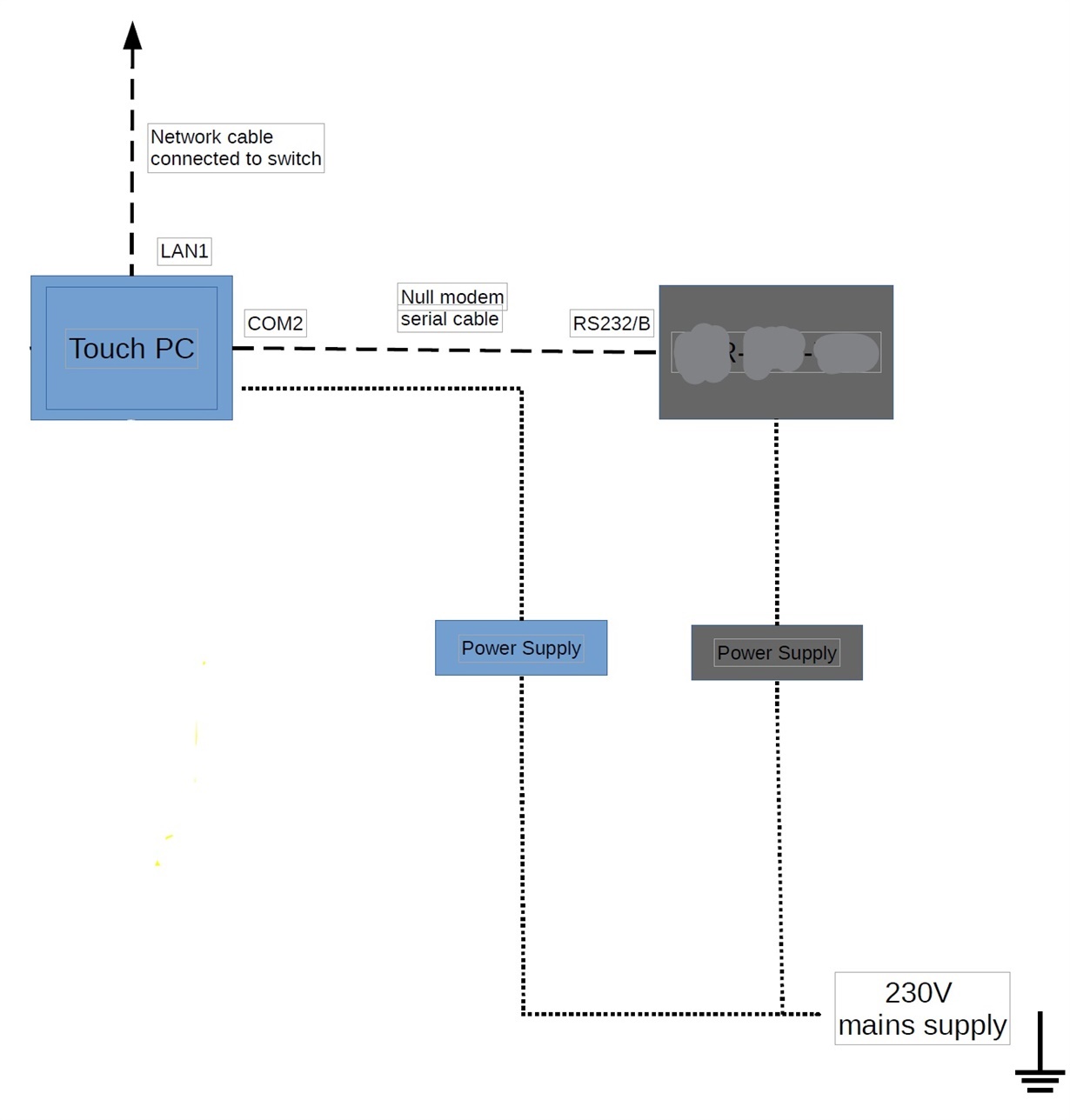

The TRS213 is used to level shipft and protect all the pins of a standard serial port. The customer uses the RI pin as 12V supply (POS type application) which under normal cirsumstances does not interfere with the serial port functionality (RX/TX, RTS/CTS are used).

The customer's use case has a powerful 12V/2A power supply attached to RI, so a high current could flow. Far above what a serial port could source.

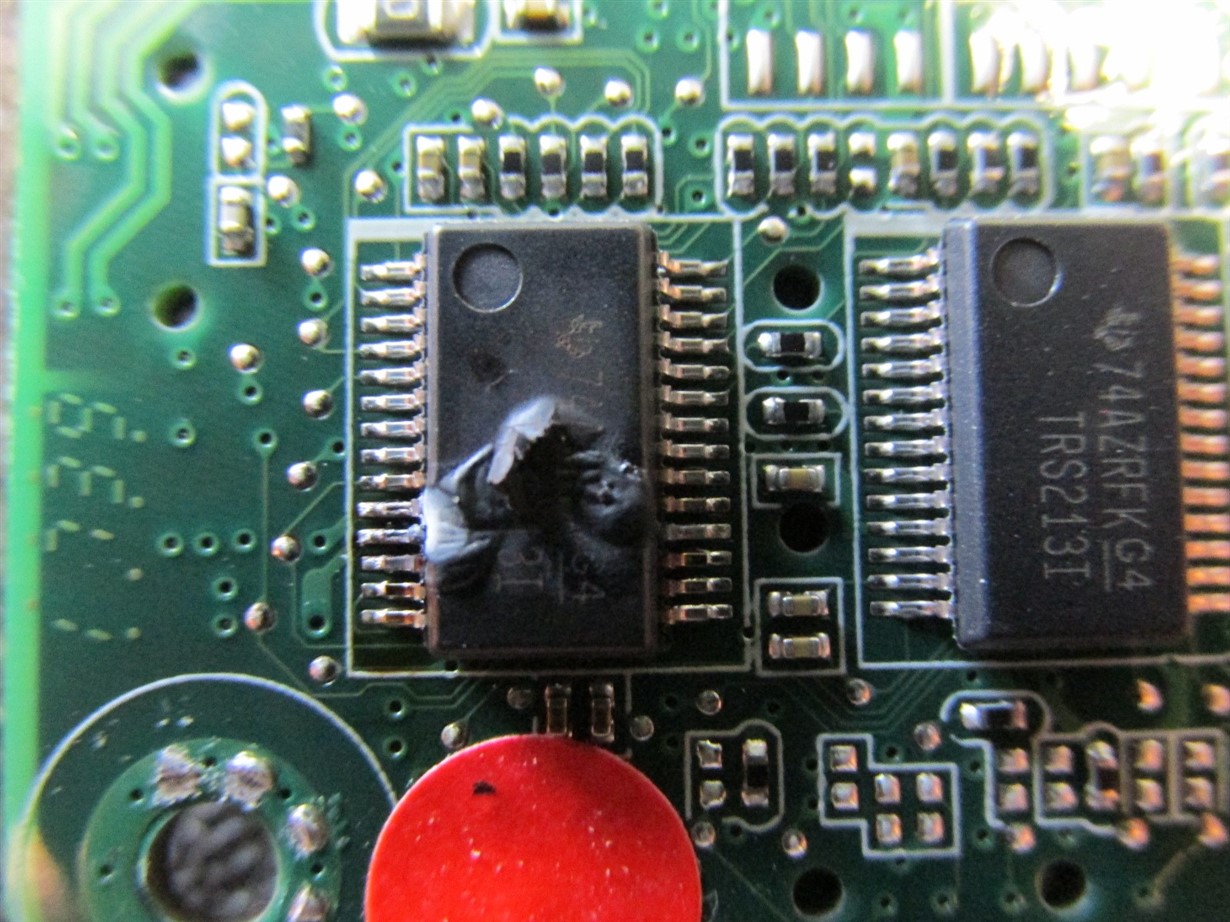

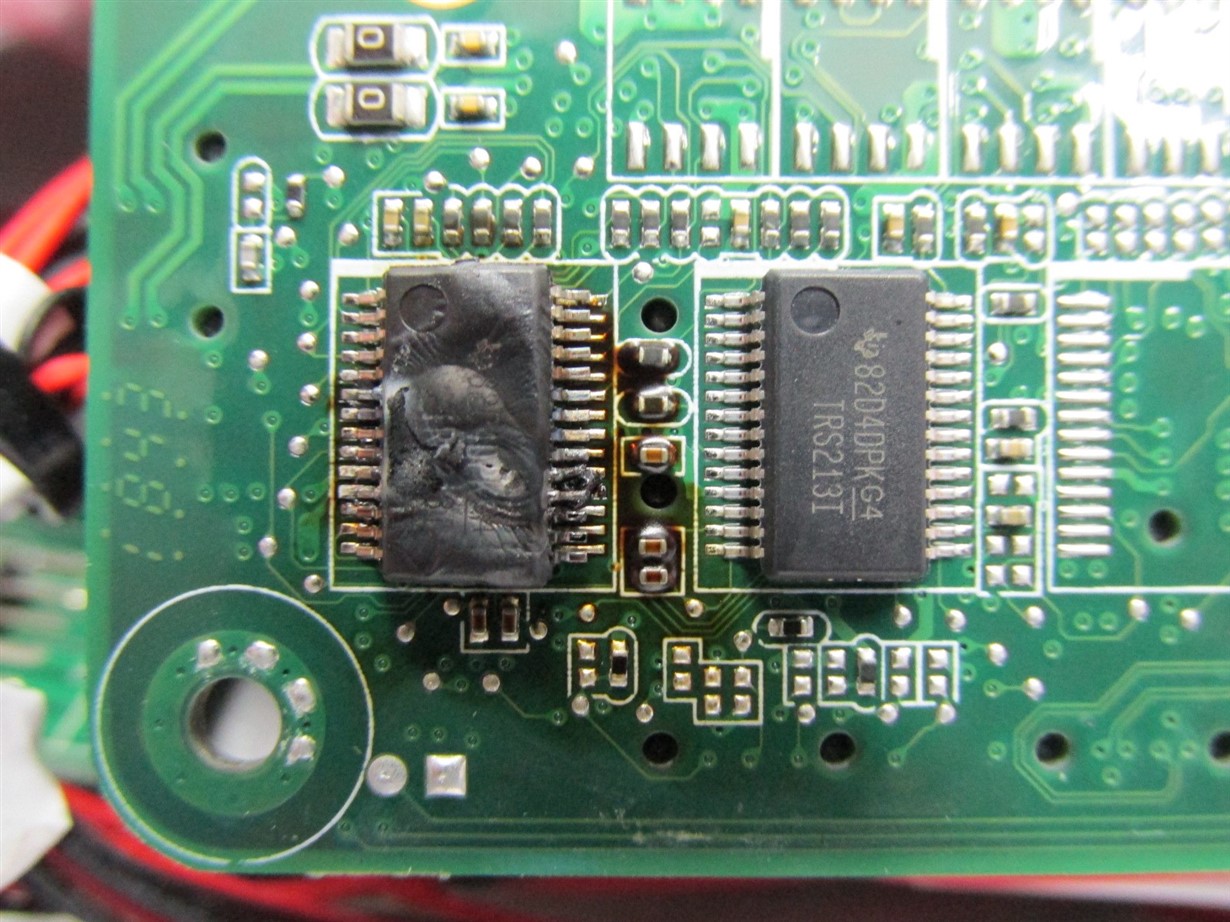

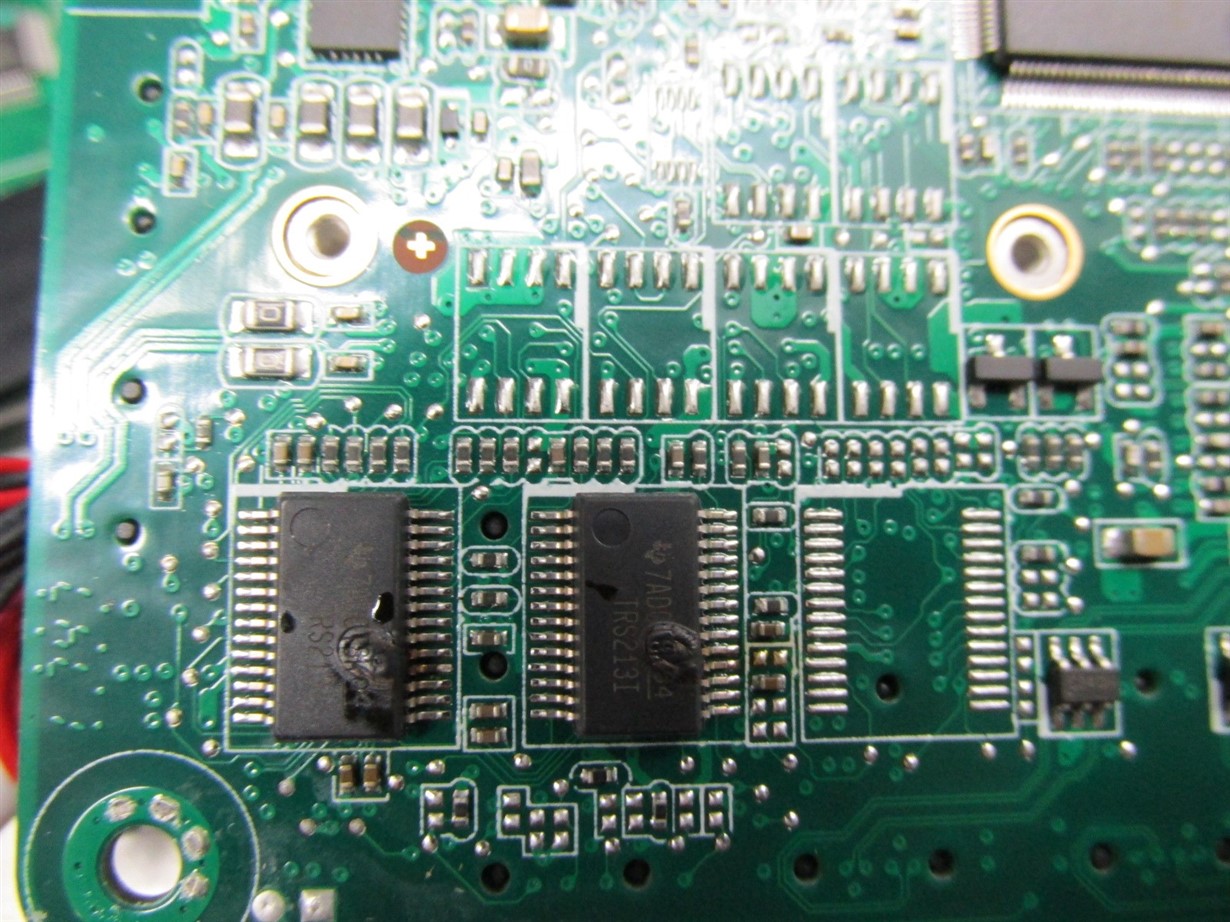

After an ESD event in the lab, when a 12V/2A power supply is attached to RI we can recreate the IC burn up. See pictures below.

In case of an ESD event on the RI pin, I assume that some kind of internal TVS diode starts conducting.

At what voltage would the TVS stop conducting?

Is this voltage current dependent?

Could this scenario explain the result we see?

Best regards,

Lo2