Hi TI experts,

My customer is using ISO1050 now. In the past, they use one master and ten slaves in one CAN BUS.

Recently, they want to use one master and 30 slaves in one CAN BUS but failed. (The CAN BUS wire on each board is 30cm. The wire between two boards is 15cm. one machine includes 10 boards. The wire between two machines is 1.8m. So the total length of the whole CAN system is about 30m)

- Testing results:

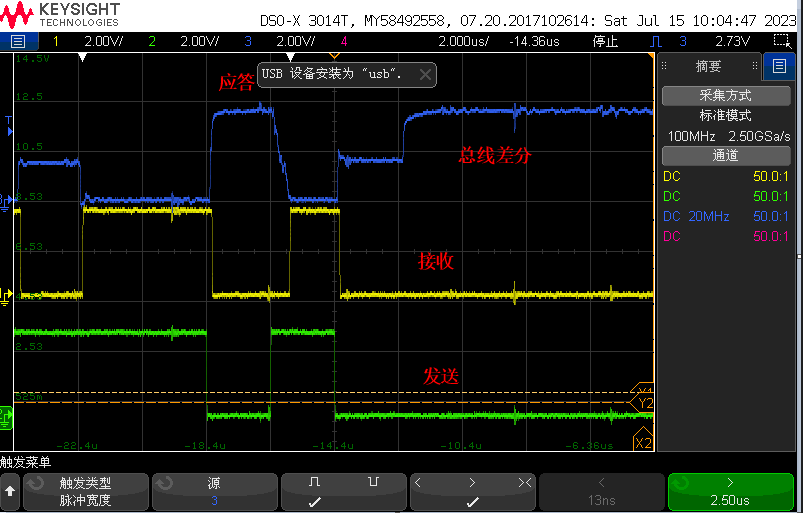

The result is a last part of a packet, which is collected from one of slave. Yellow wire is TX(ISO1050 to F280049). Green wire is RX(F280049 to ISO1050). Blue wire is differential signal on the CAN BUS.

You can see that after a master signal is sent, all the slaves alse responded. But the fall time of blue signal is slow. Eventually, there are 6 cycles of wrong signals on the CAN BUS.

is it due to the connectors and shielded twisted pair they ues? (Capacitor value on the line is so big to make the fall edge slow?)