Hi toghter,

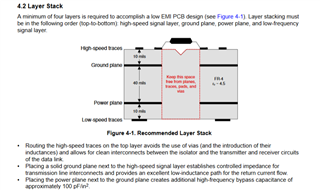

In the TI Digital Isolator Design Guide SLLA284G it is mentioned to keep the space under the ISOxxxx component free of planes, traces, pads and vias.

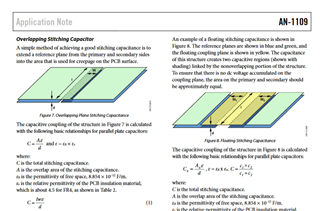

In comparison, the application note AN-1109 of Analog Devices, a guideline for PCB layouts of digital isolators (ADuM series) recommends to build an overlapping stichting capacitor beneath the isolator.

Can somebody explain, why the recommendations are so different for the ground plane design for digital isolators of TI and Analog Devices? Is it caused by the coupling technology? ISOxxx isolators use a capacitive coupling. In comparision, The ADuMxxxx isolators use a magnetic coupling.

Thanks a lot for your answer and explanation.

Best regard,

Basil