Other Parts Discussed in Thread: TCA9511A, TCA4307,

Hello,

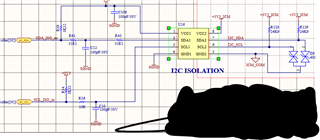

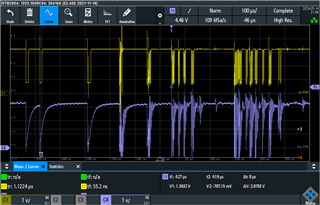

The system I have is a back-plane board where power modules can hot plug into. Below screen shot is triggered on the hot-plug event.

Blue trace is I2C bus side SDA, and yellow trace is SDA micro side.

I thought the I2C bus side (side 2) should deal better (not such a large discharge). Is this what should be expected?

The blue trace hit's about - 0.7V, which is outside of the - 0.5V absolute specification; but, would this be classified as an ESD like event? So, can tolerate much higher voltages but much smaller energy.