Other Parts Discussed in Thread: POWERSTAGE-DESIGNER

Tool/software:

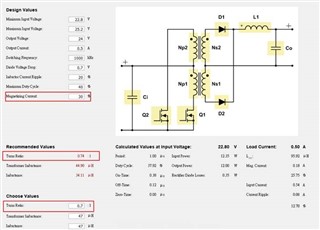

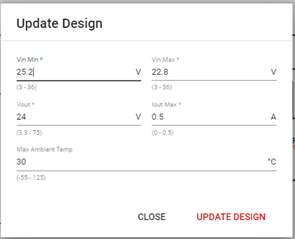

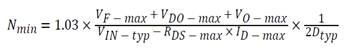

Customer would like to do the bias power of gate driver for AC inverter. Is there ref. design similar to below condition?

Input Voltage: 24V+/-5%

Isolated Output Voltage: 24V (x3)

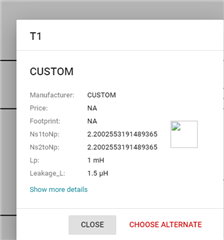

Remark: There're three 24V ISO outputs for IGBT's bias power. The total output power is about 5W. Could SN6507 using only one transformer to do so? thanks.

Regards

Brian