Other Parts Discussed in Thread: ISO35, ISO35T

Hi,

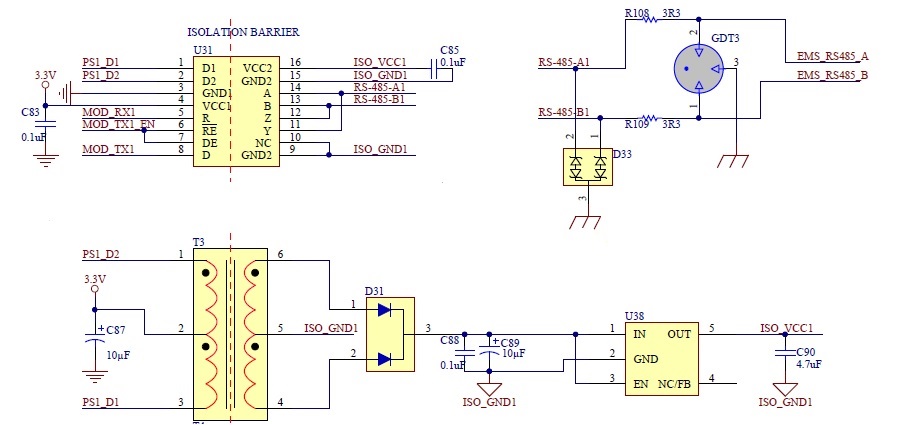

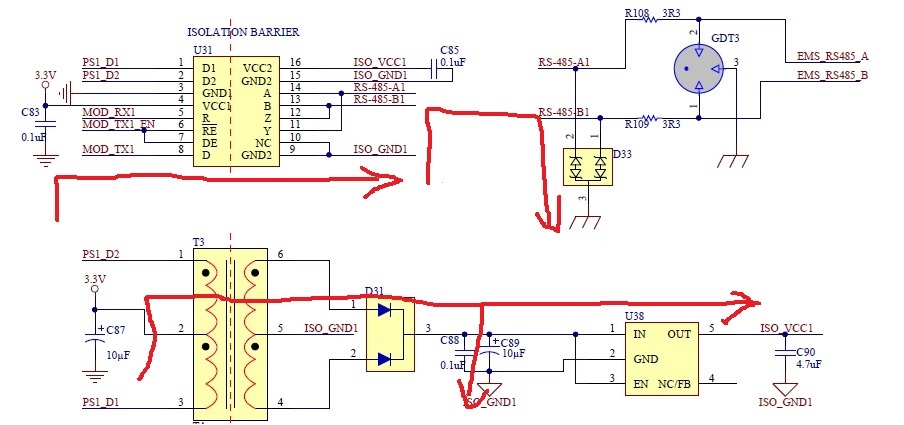

I am using ISO35 for RS485 communication in my design but after the hi-pot test at 1700V, this transceiver does not work anymore. I have found out the transceiver and rectifier on secondary side of HF transformer were both damaged.

As stated by TI, this transceiver is rated for 2500Vrms of isolation.

Is there anyone has ever experienced this before?

Any response/advice would be highly appreciated.

Thanks